Looking to load and unload block pallets or air cargo and ULDs (Unit Load Devices) quickly and safely? With our Built-in Rollerbed system, you can make the handling of any load an efficient, simple and safe operation.

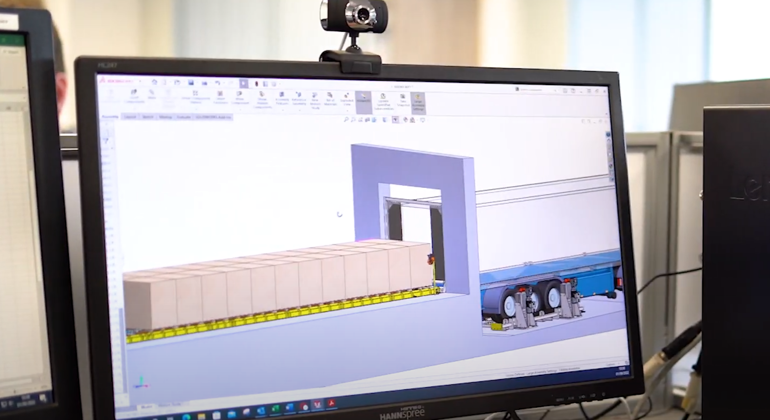

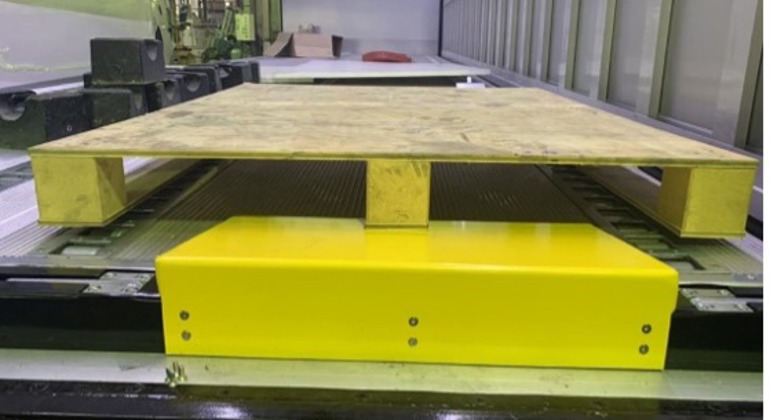

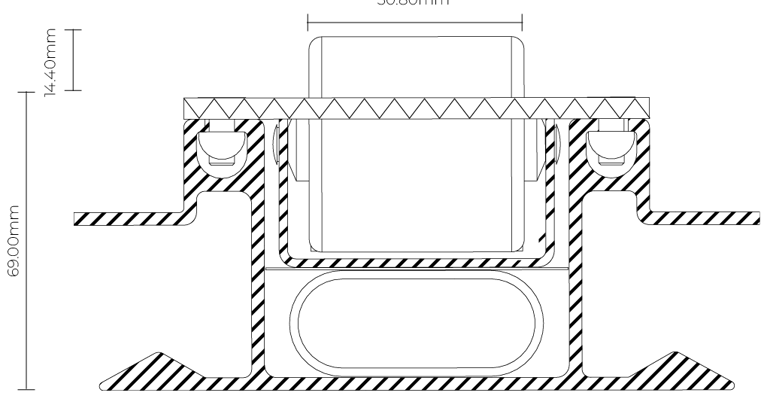

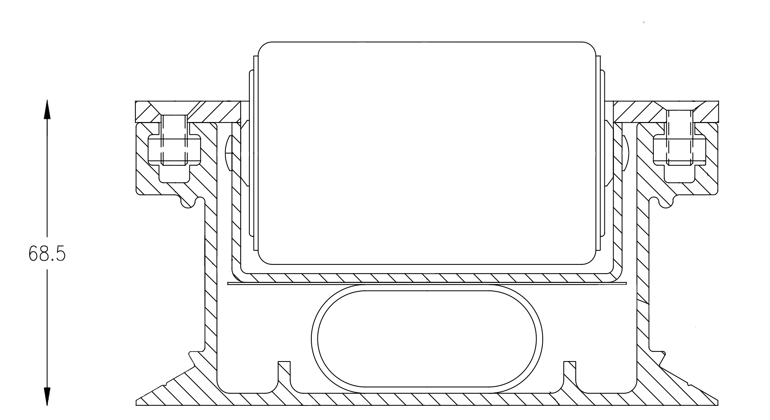

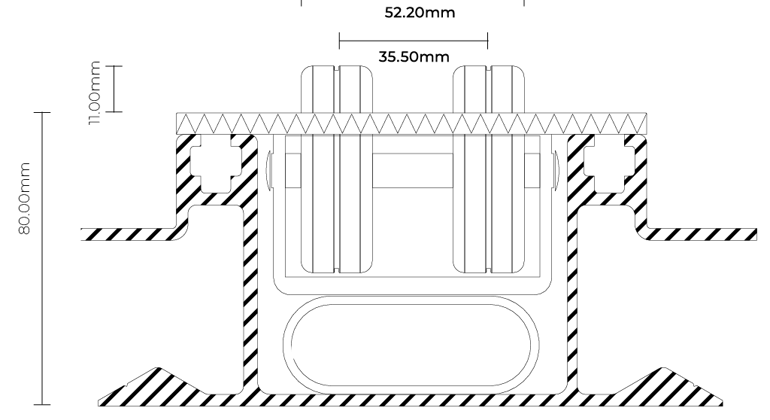

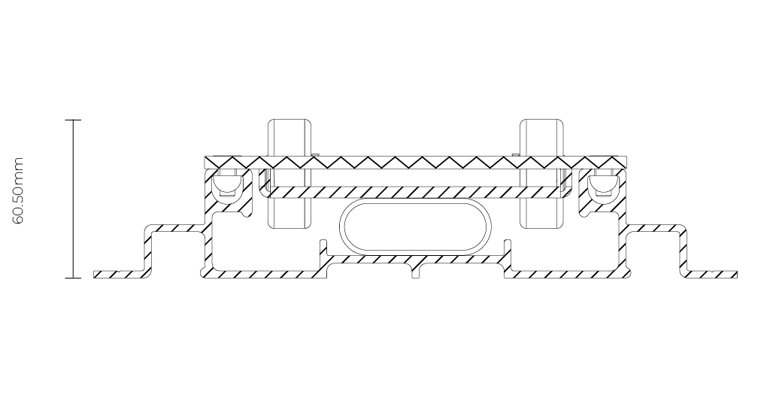

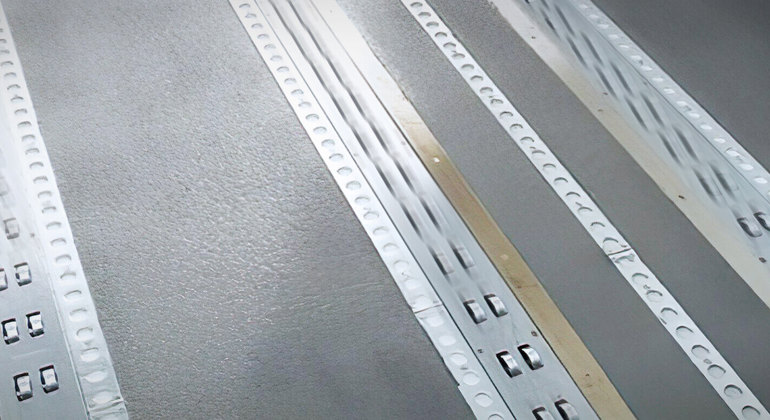

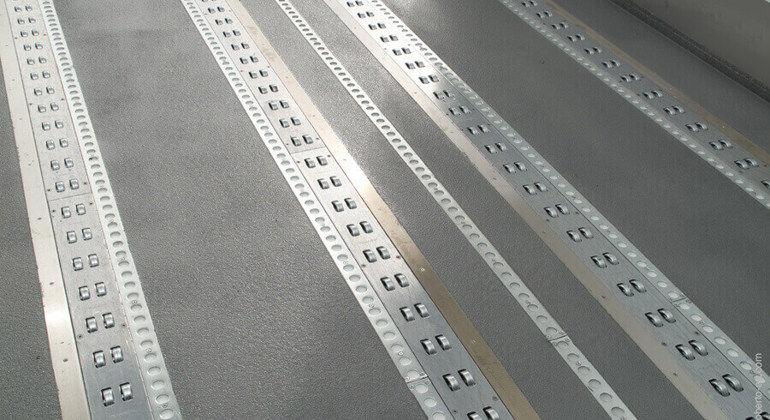

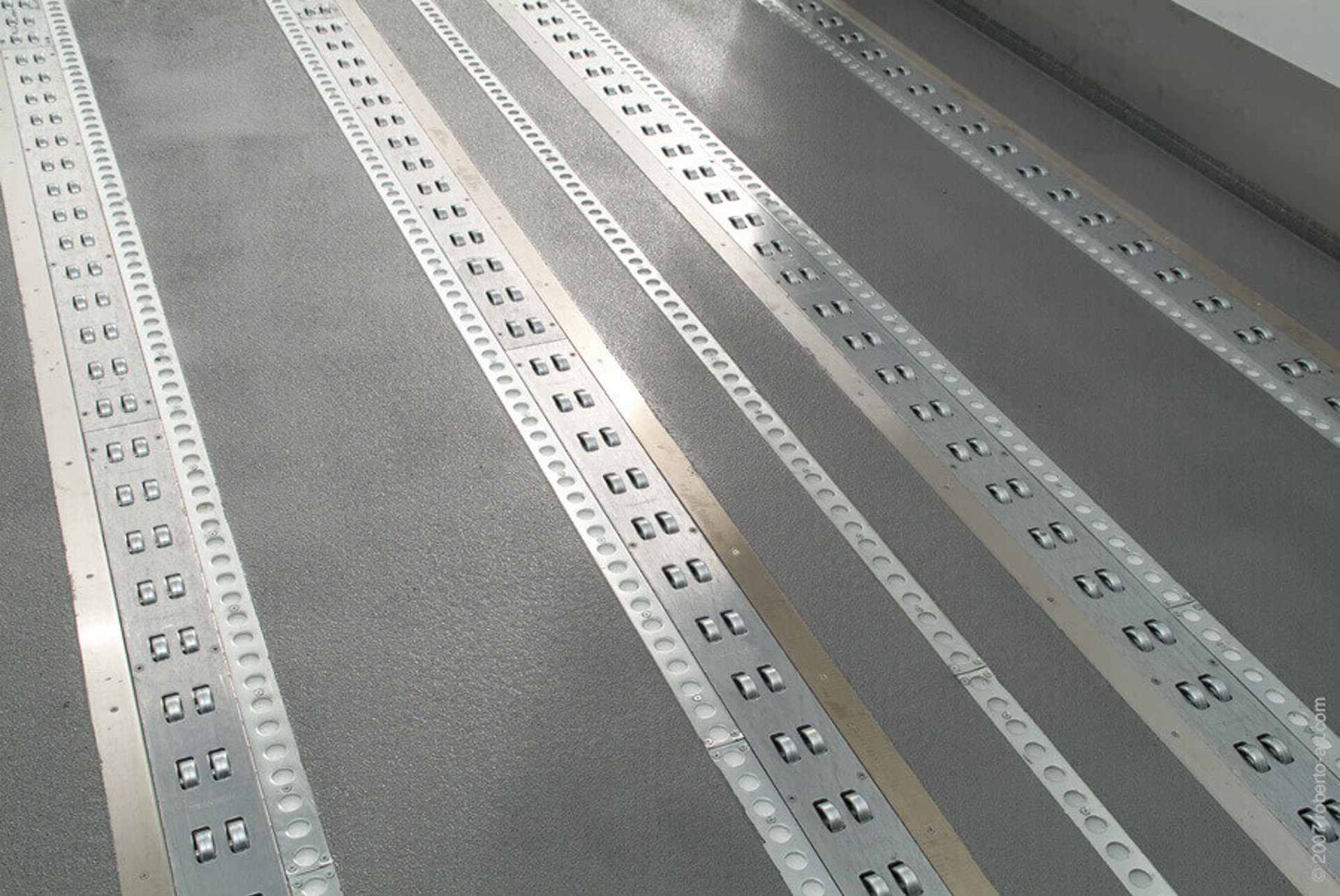

The built-in rollerbed system is integrated into the floor of a transport vehicle and is perfect for those seeking a loading and unloading solution while retaining maximum internal trailer height.

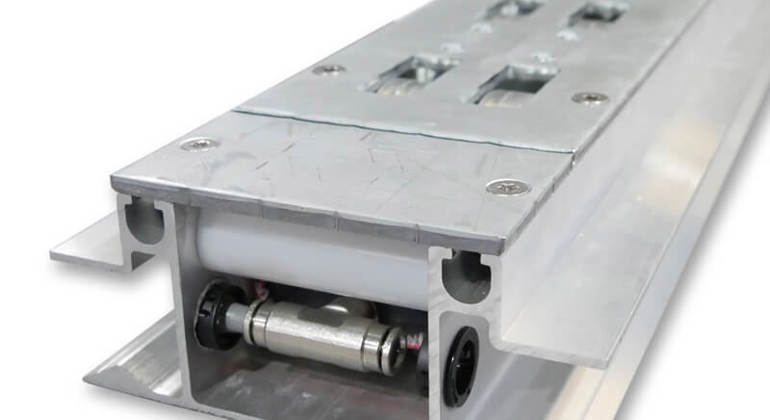

With a lifting capacity of 550kg per module per metre, thanks to our Pneumatic Rollertrack (PRT) technology which uses air to safely lift and lower the rollers, we can offer the ideal solution to meet your needs, no matter the load.

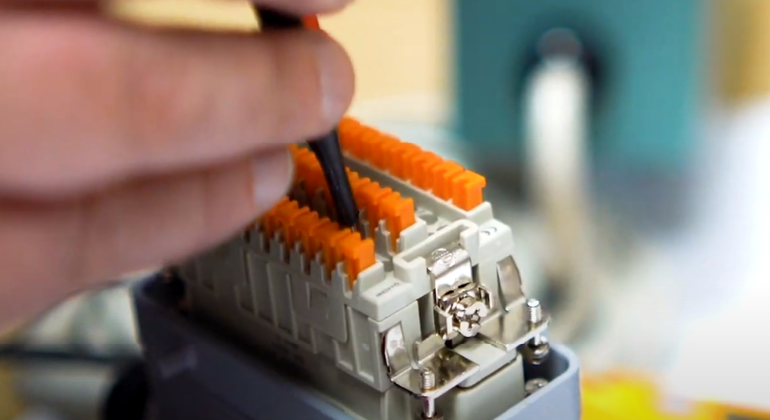

The pneumatic rise and fall rollers can be operated by a single user, either from the trailer-mounted control box or a pendant switch control, meaning even the heaviest loads can be loaded and unloaded by a single employee.

Read on to find out how the features of our built-in rollerbed system can benefit your business.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW