A van is an important tool whether you’re working in logistics or in another trade. The extra space allows you to carry bulky loads and items, equipment tools and more, depending on your van’s commercial purpose. Maybe you’re a supplier, delivering materials to a manufacturer or stock to a retailer. The van will serve you exceptionally well.

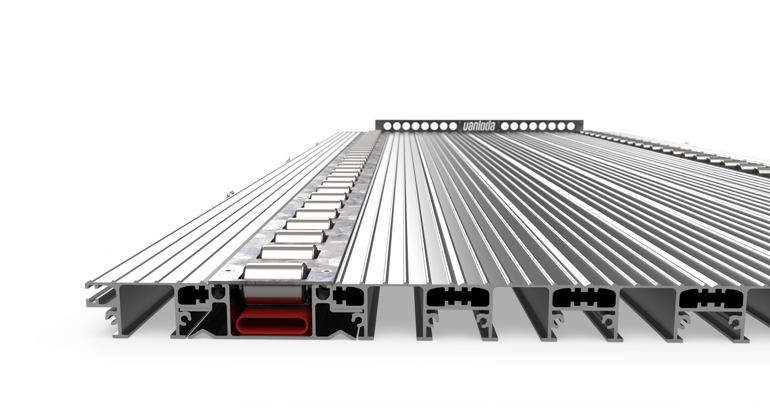

Below is an in-depth look at vans. We discuss van sizes and how to understand them, aspects to consider when choosing a van, how to choose the right van and also how to load and unload a van safely. We’ll also explain a little about one of our own loading solutions, the cargo van pallet loading system (our Modular Rollerbed System: Van), which can make it much safer and easier to load and unload a van.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW