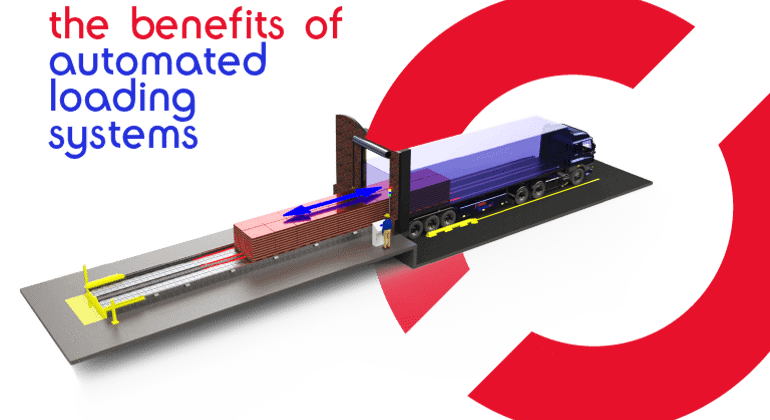

what are slipchain pallet loading solutions?

Shipping goods from factories to warehouses? Lighten the load with our Slipchain pallet loading solution.

Combining a heavy duty, pneumatically activated rise and fall chain with a Rollertrack system for trailer and dock, it’s ideal for loading and unloading palletised goods.

Whatever your setup, the system’s durable, modular design makes it easy to integrate into any building or trailer. With minimal civil works or trailer adaptations required, simply connect it directly to your production line conveyors, or use forklifts and AGVs to place your cargo onto the system.

Safe, easy, and fast. Offering unparalleled strength in design. And the lowest total cost of ownership (TCO) for your business. That’s the Joloda Hydraroll difference

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW