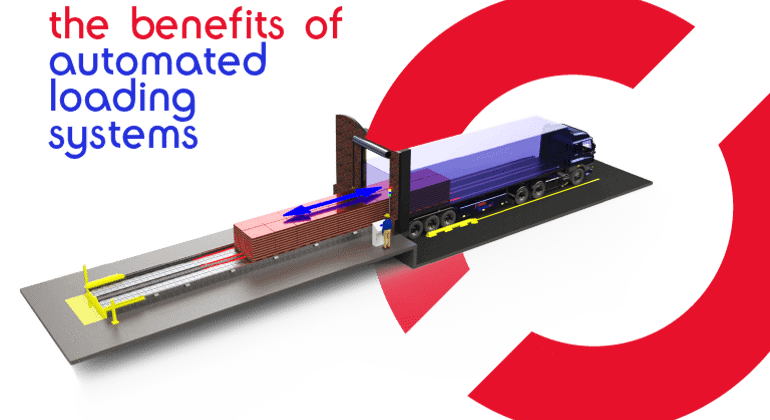

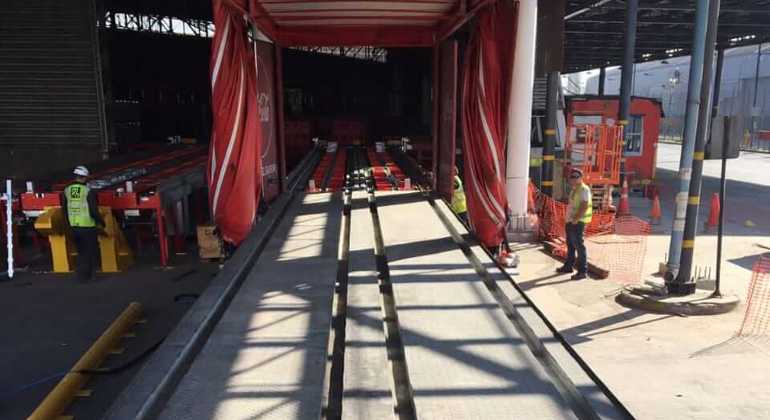

In the scenario that a business produces and ships a high number of pallets each day, we’ve put together an automated loading system typical business case example to help explain the benefits and how an ROI can be achieved with the investment of an automated loading system.

If a business is running a shuttle run from a factory to a warehouse and back again, they’ll benefit from an automated loading system with fewer people, trucks and forklifts.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW