Loading and unloading containers is a common process in factories, construction sites and other industrial environments. A forklift is a familiar vehicle in the warehouse to carry out the lifting of heavy loads and manage stock storage.

However, many warehouse accidents are caused by forklifts. The average weight of a forklift can reach up to 9,000 pounds, which is thrice the size of a medium-sized automobile. Because of its weight and reach, forklifts can tip over, causing accidents and injuries. Although there are numerous hazards with operating forklifts, the four main areas of concern involve the use of attachments, such as clamps; operating in areas where pedestrians are present; the work environment, including uneven flooring and poor ventilation; the load.

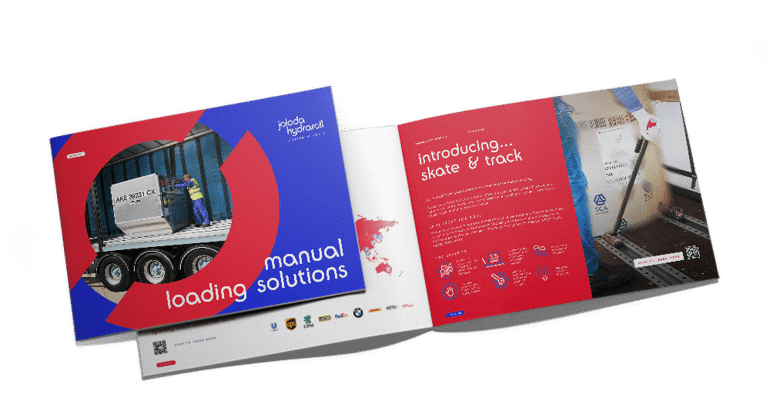

At Joloda, we supply safer, more efficient equipment to suit your container transport needs: Container Loading Systems.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW