If you’re operating in logistics or related fields, you’ll have come across the abbreviation ‘D2C’, which stands for ‘direct-to-consumer’ and has exploded, as businesses reap the benefits from this approach to fulfilment. D2C is all about delivering directly to consumers, rather than going through a third-party fulfilment service.

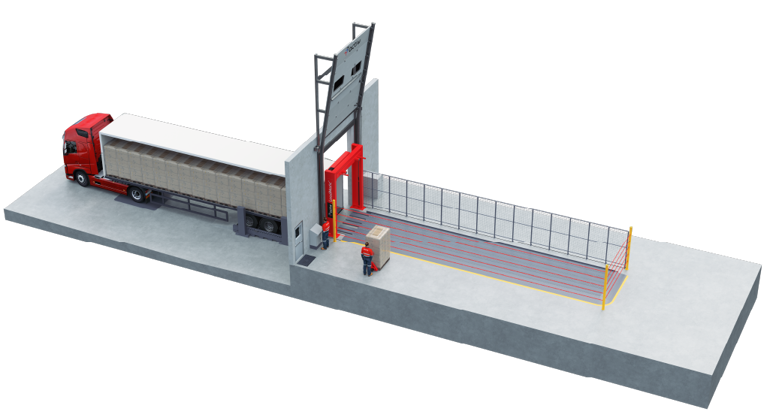

One piece of equipment businesses might use to speed up their D2C operations is an automated loading system, such as the equipment sold by Actiw, a division of the Joloda Hydraroll Group.

These loading systems are especially handy for third-party logistics (3PL) businesses, who often don’t wish to modify their trailers, because Actiw’s equipment doesn’t require permanent modification of trailers. This automated loading equipment can really mark a turning point in your operations by boosting efficiency, cutting costs and improving handling safety, to name but a few of the benefits, which we’ll explore further in this article.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW