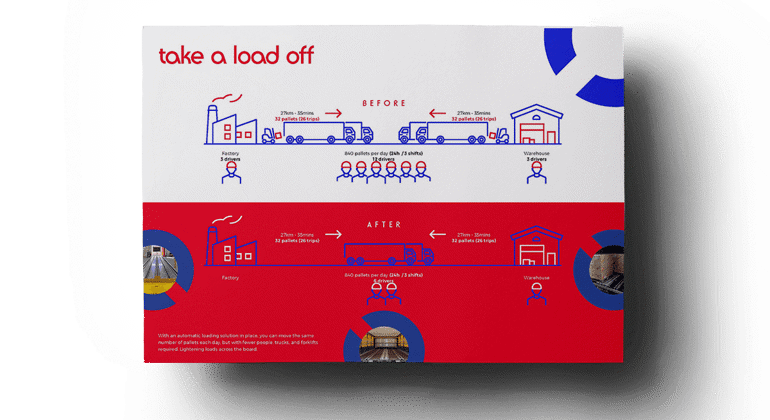

Automated material handling systems (AMHS) are essential pieces of equipment for moving materials and other items around warehouses and manufacturing facilities. These technology-driven systems combine robotics, machinery, control systems and software to automate tasks humans perform manually. They help businesses to manage storage, control and movement of materials throughout distribution, transportation, consumption and disposal processes.

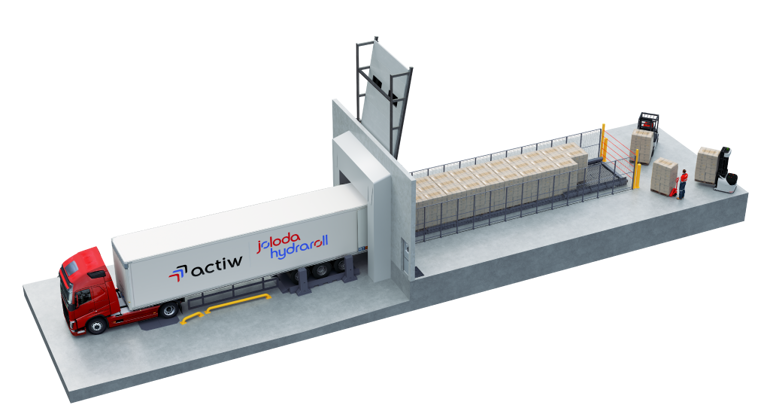

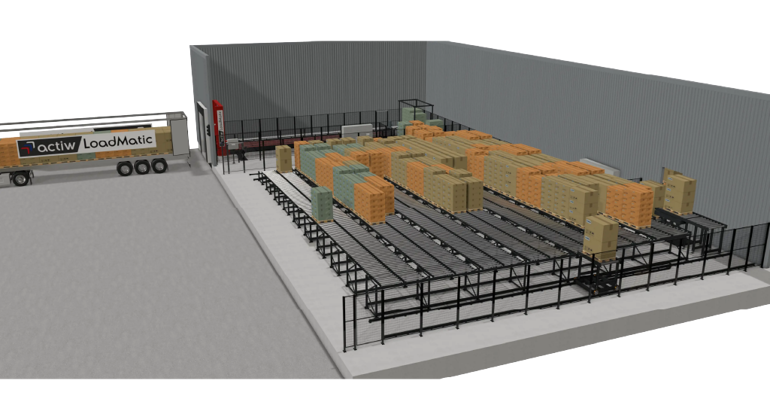

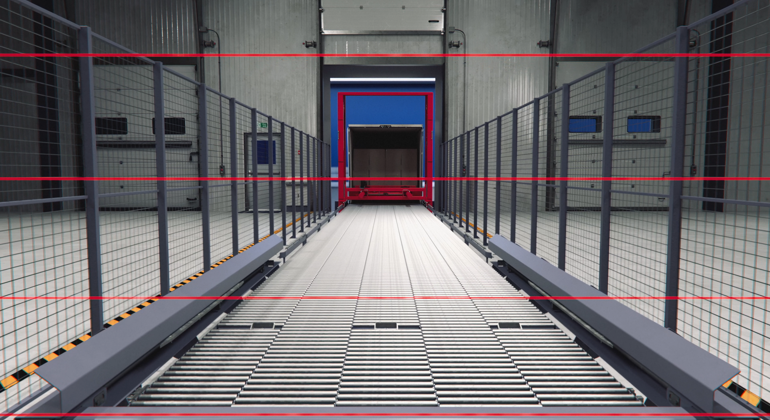

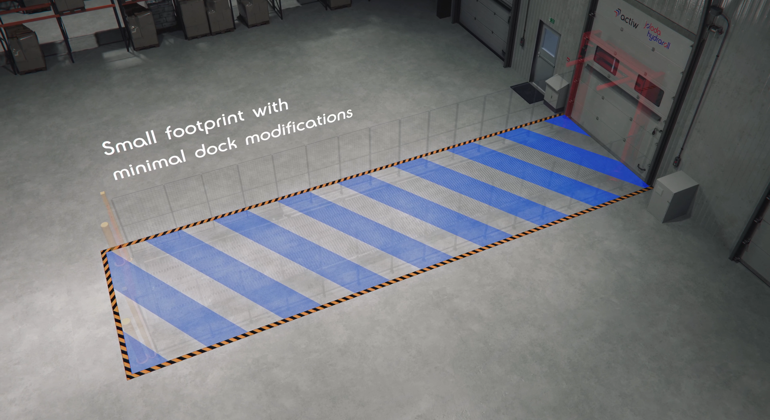

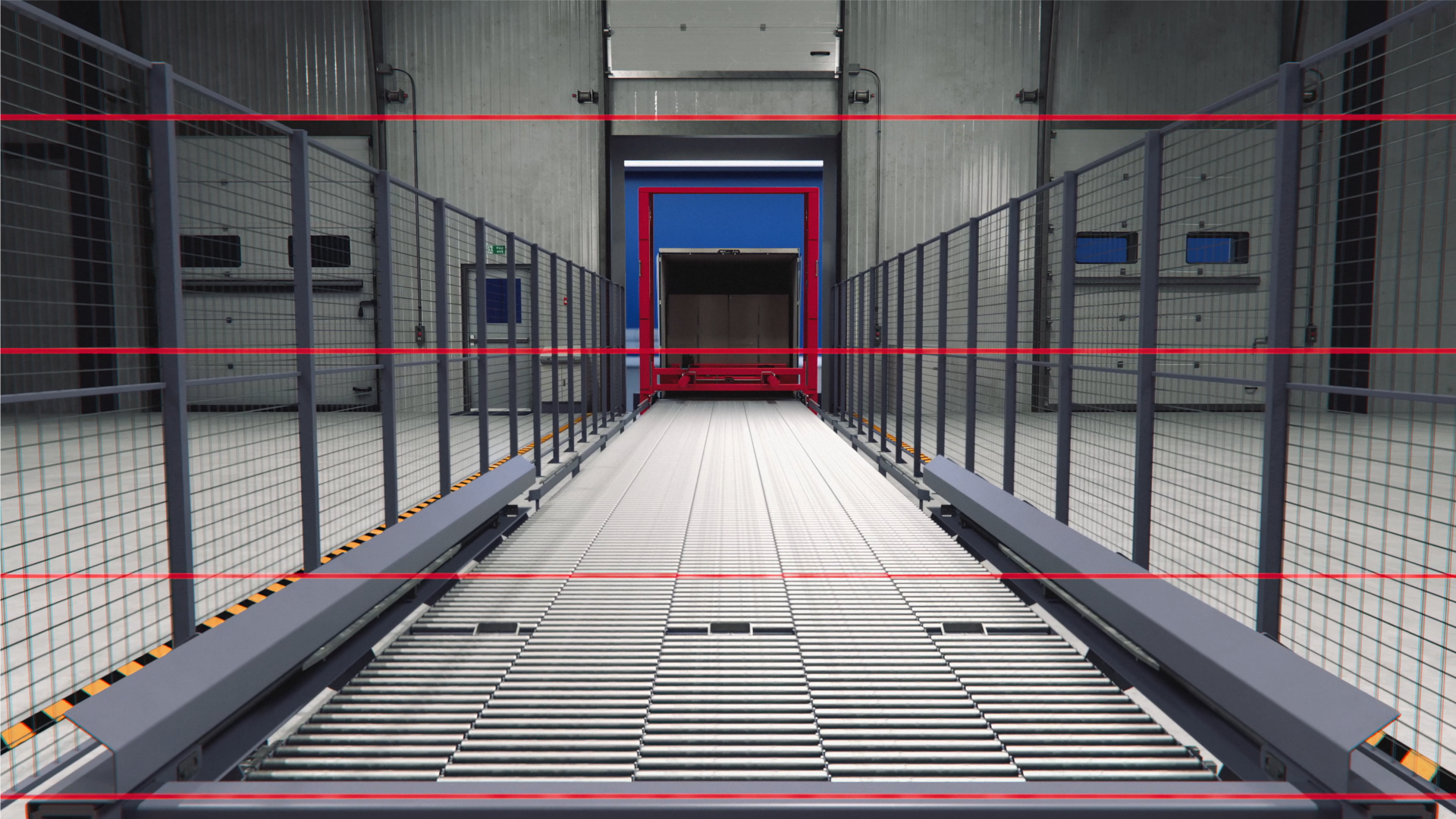

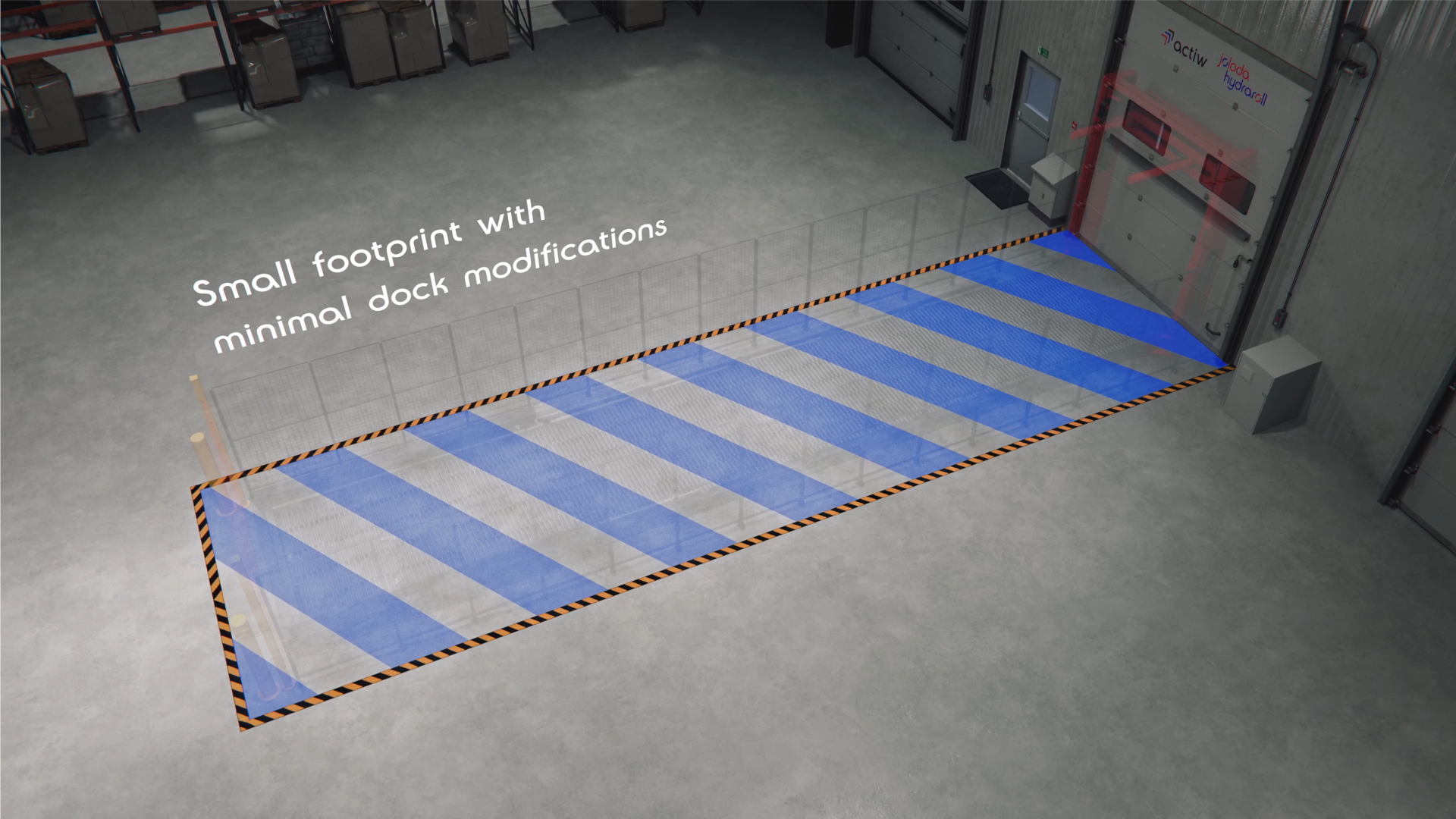

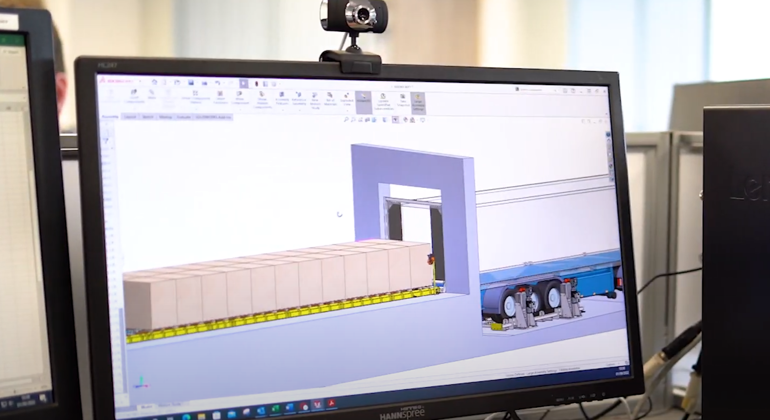

AMHS are like our Automated Trailer Loading Systems (ATLS), which are specially designed to support businesses in loading and unloading trailers with materials and transferring them from the loading dock to the warehouse facility, and vice versa. Below we look at automated material handling systems, their functions, benefits and how they support loading and unloading.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW