Automated guide vehicles (AGVs)

These are mainly used for transporting stock or materials around the warehouse, often from section to section, or for transferring picked stock to a packaging area.

Autonomous mobile robots

These are sophisticated, multipurpose robots that can move around dynamic warehouse environments on their own and operate without any extra guidance. Warehouses call upon them for a number of tasks. They’re good for moving stock around the warehouse and for bringing it to pickers and packers. It’s even possible to program them to move ahead of the pickers to the next stop on the route. The advanced sensors on autonomous mobile robots can identify and process the information on packaging, which makes it possible to implement them for inventory checks, sorting and put-away tasks.

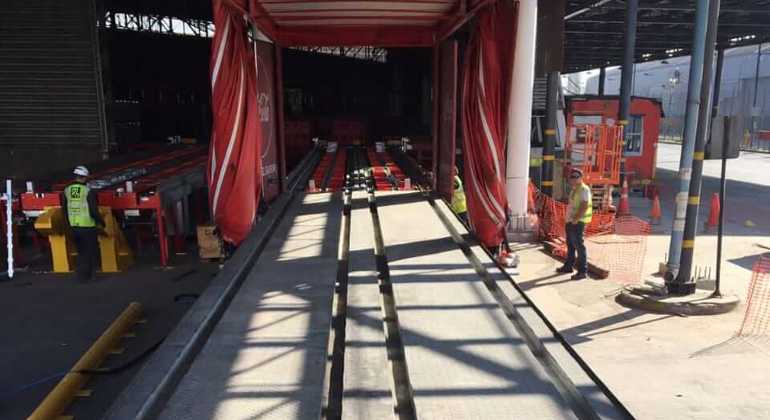

Automated storage and retrieval systems

These are computer-controlled robotic systems that can automate the shipping and put away of goods. These typically large-scale systems consist of a crane or shuttle on fixed tracks that pick items up or put them down via the aisles in a warehouse.

Robotic arms

These versatile robots take care of unsafe jobs for the workers. They consist of a multi-jointed limb that can pick up stock, move it or put it down. Often, warehouses will use them to manage pallets and heavy items for storage, picking and packing, and receiving and loading vehicles.

Unmanned aerial vehicles (UAVs)

People often refer to AUVs as ‘drones’, and this type of robot combines functionality and flight in logistics. Companies can equip them with cameras and scanners for accuracy and for stocktaking, as well as systems for lifting moving lightweight cargo.