What is OpEx in a Warehouse?

OpEx (Operating Expenditure) in a warehouse refers to the ongoing costs required to run daily operations. This includes labour, utilities, equipment maintenance, consumables, software subscriptions, training, and all repetitive expenses that recur month to month.

Unlike CapEx, OpEx directly impacts a warehouse’s cost-per-pick, cost-per-pallet moved, and overall profitability of fulfilment operations.

What is CapEx in Warehouse Operations?

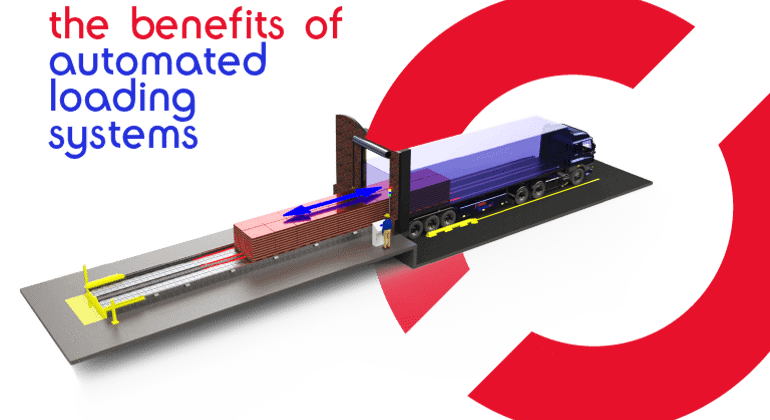

CapEx (Capital Expenditure) refers to the upfront investment made to acquire physical assets such as racking, conveyors, forklifts, Automated Loading Systems, or warehouse management software licences. These are long-term purchases that are capitalised and depreciated over time.

How Does Warehouse Automation Reduce OpEx?

Warehouse automation reduces OpEx by lowering labour costs, minimising manual handling, reducing human error, and improving process speed.

Automated systems work consistently without breaks, fatigue, or productivity dips, allowing businesses to move more goods with fewer resources. Automation also reduces product damage, improves inventory accuracy, and lowers the cost of rework, contributing to sustained reductions in operational spending.