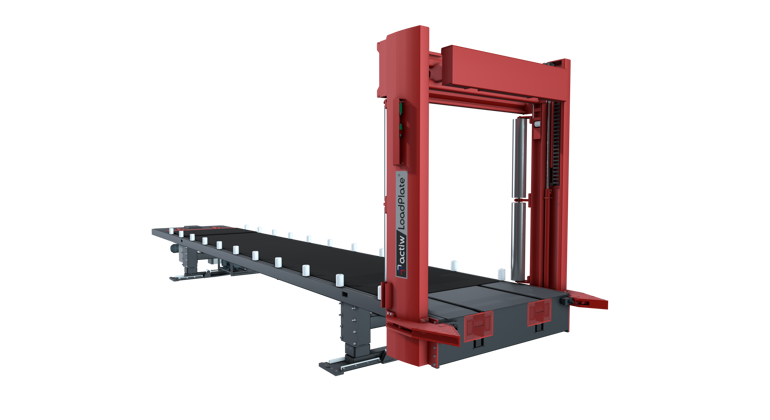

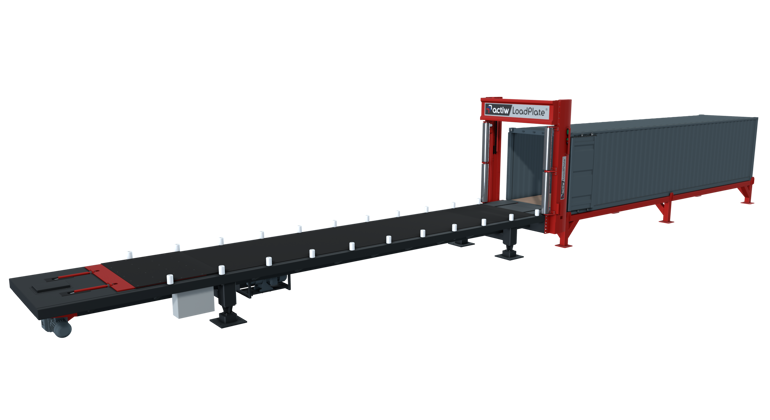

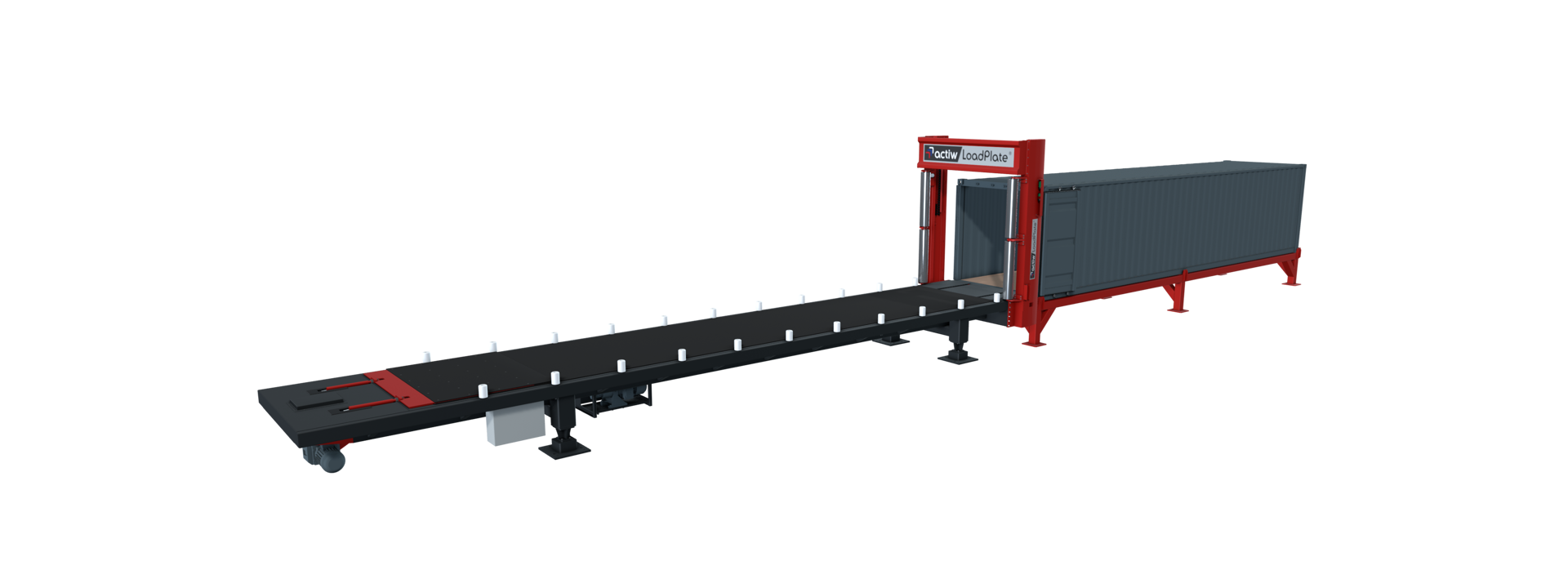

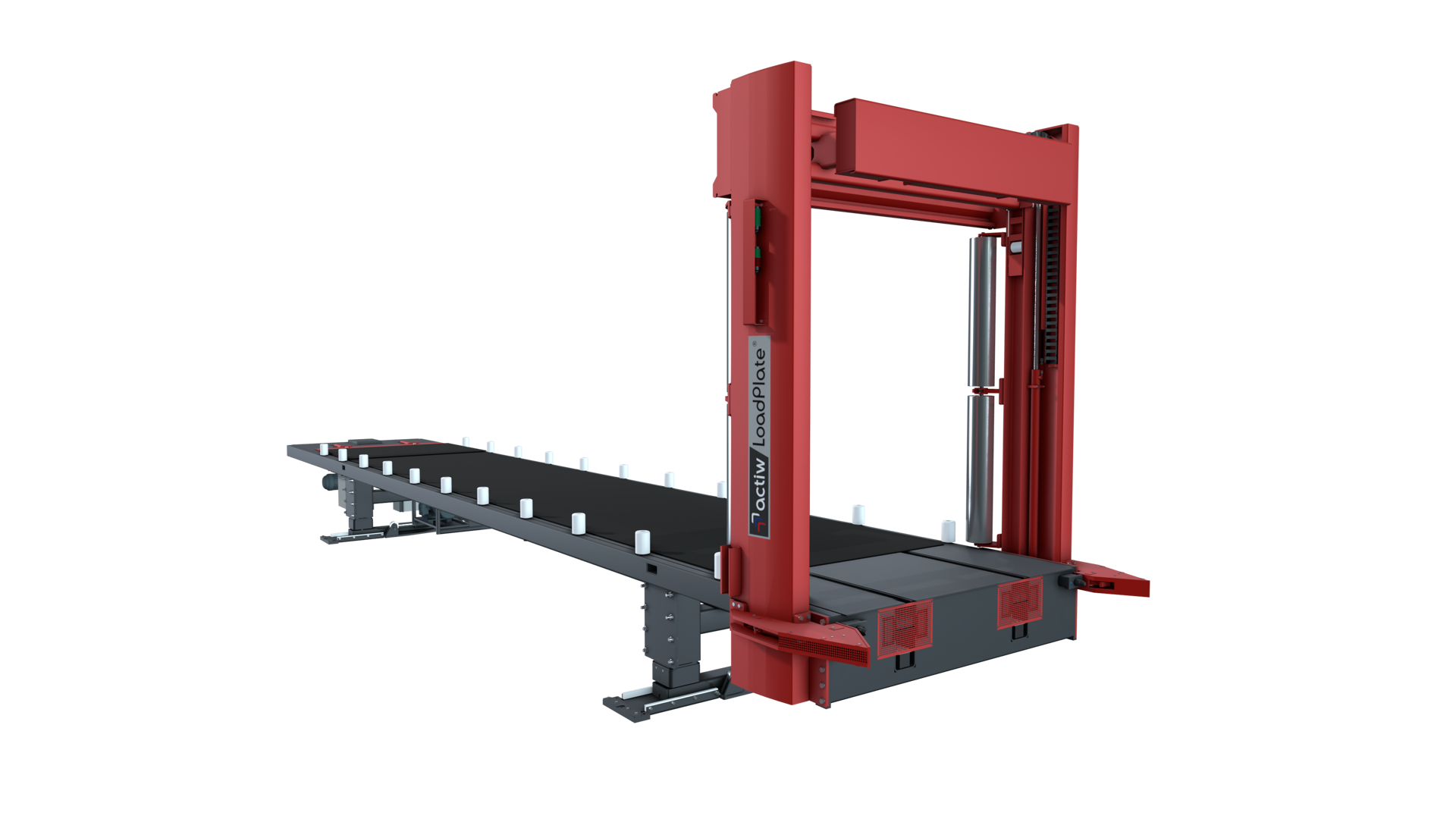

LoadPlate® is an automatic loading machine for shipping containers and regular, non-modified trucks.

Companies around the world use the LoadPlate system every day for the loading of complex or long cargo, such as steel or lumber.

The LoadPlate container loading solution can load 30 tons of cargo into a 40-foot container in just 5 minutes. Load your cargo onto the system using a forklift or crane, then it will be loaded into the shipping container or truck in one shot. LoadPlate was developed to improve our customers’ loading operations and was first introduced into the market in 2001.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW