Updated 19th December 2025

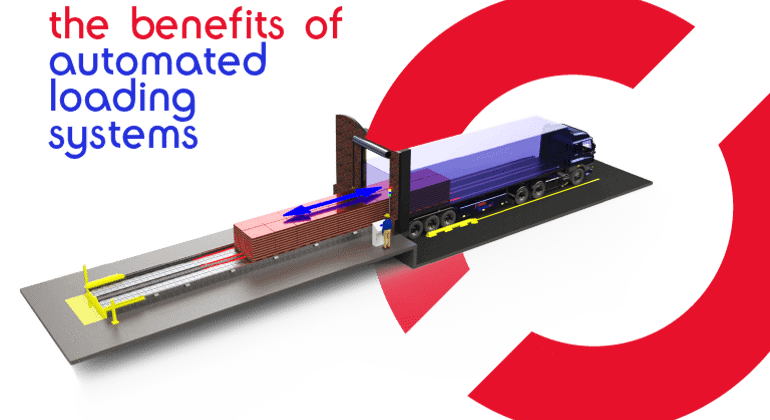

Loading and unloading in logistics refers to the process of moving goods between vehicles, trailers, and warehouses during transport and distribution. These operations are critical to warehouse efficiency, safety, and supply chain continuity.

At Joloda Hydraroll, we have over 60 years of experience designing loading and unloading systems for warehouses, distribution centres, and high-volume logistics operations worldwide.

As demand for faster fulfilment continues to rise across retail, food, manufacturing, and e-commerce, warehouses are under increasing pressure to move goods quickly while maintaining safe loading and unloading practices. Poorly managed loading operations can lead to injuries, vehicle damage, delays, and costly disruptions.

With more drivers, warehouse operatives, and temporary workers entering the sector, understanding the most common loading and unloading challenges, and how to mitigate them, has become essential for maintaining safety, efficiency, and compliance.

Below, we explore the top five loading and unloading challenges faced by logistics and warehouse operations today, and outline how modern loading systems can help address them.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW