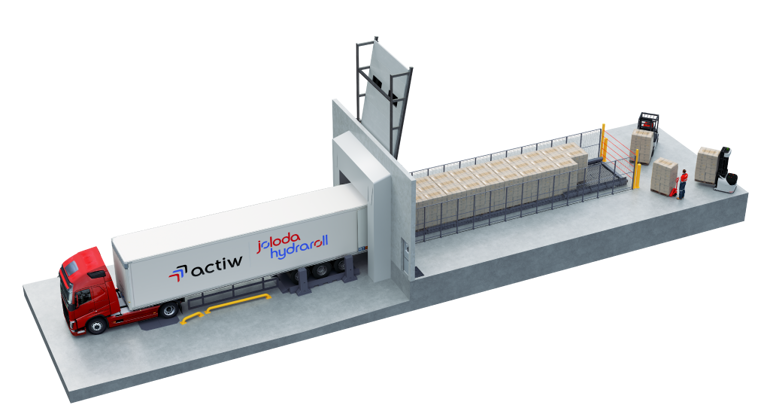

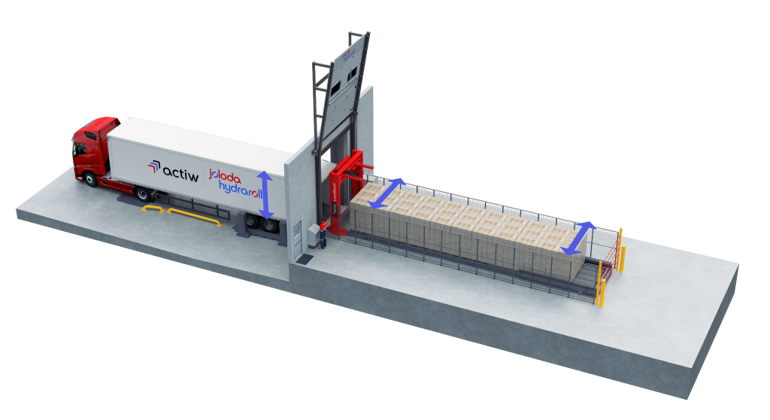

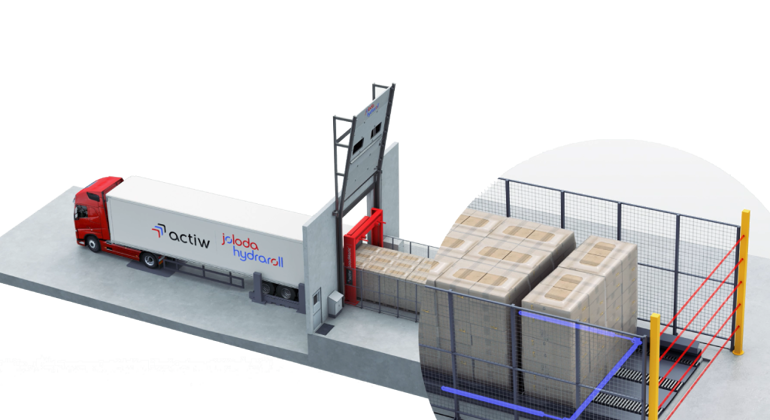

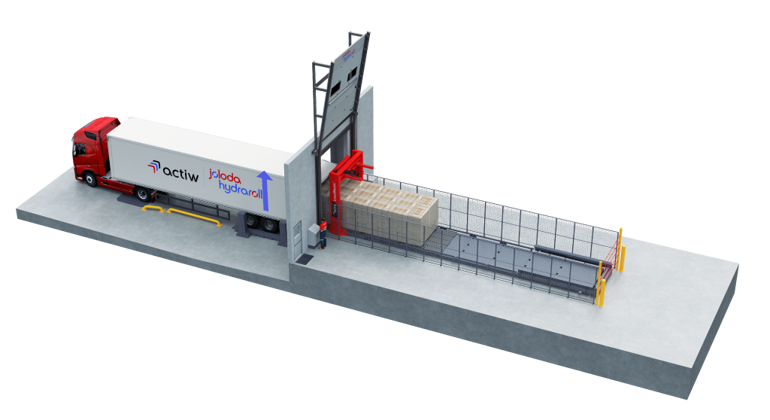

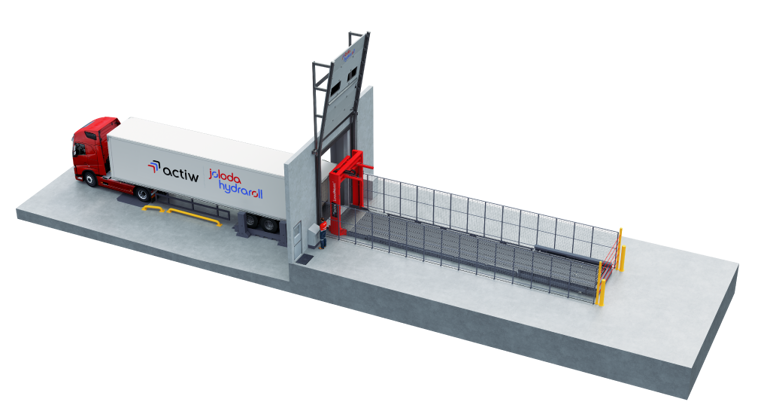

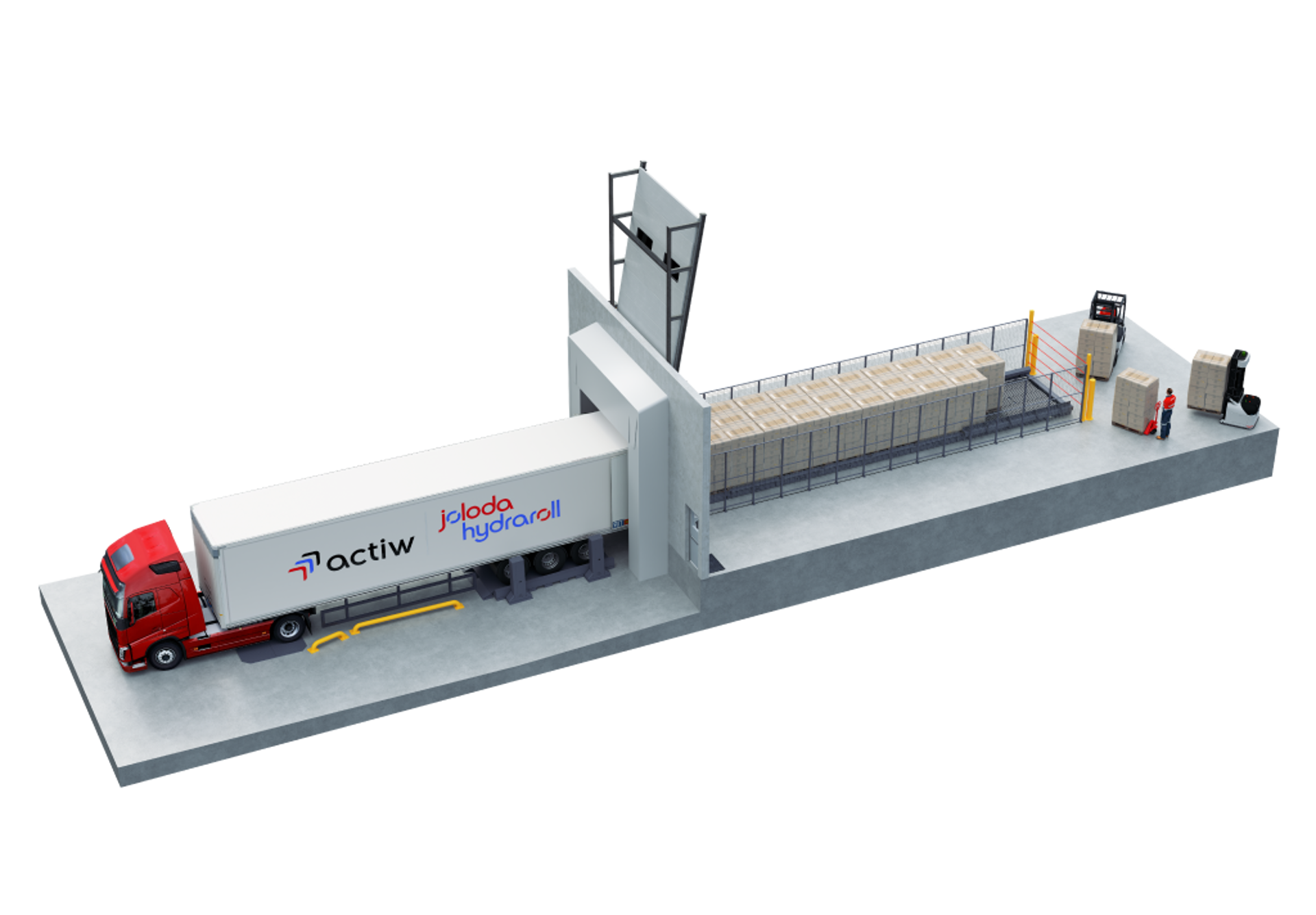

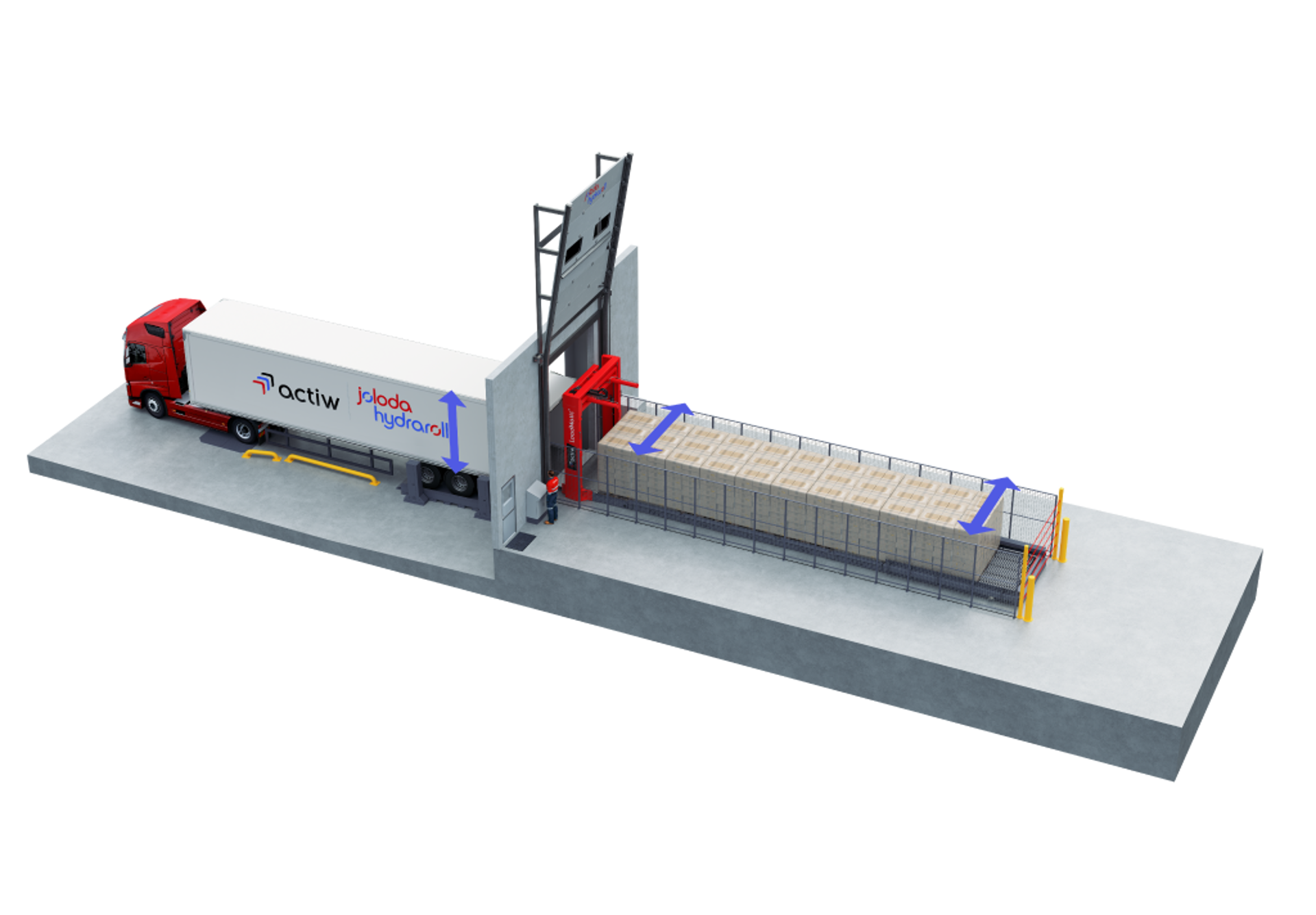

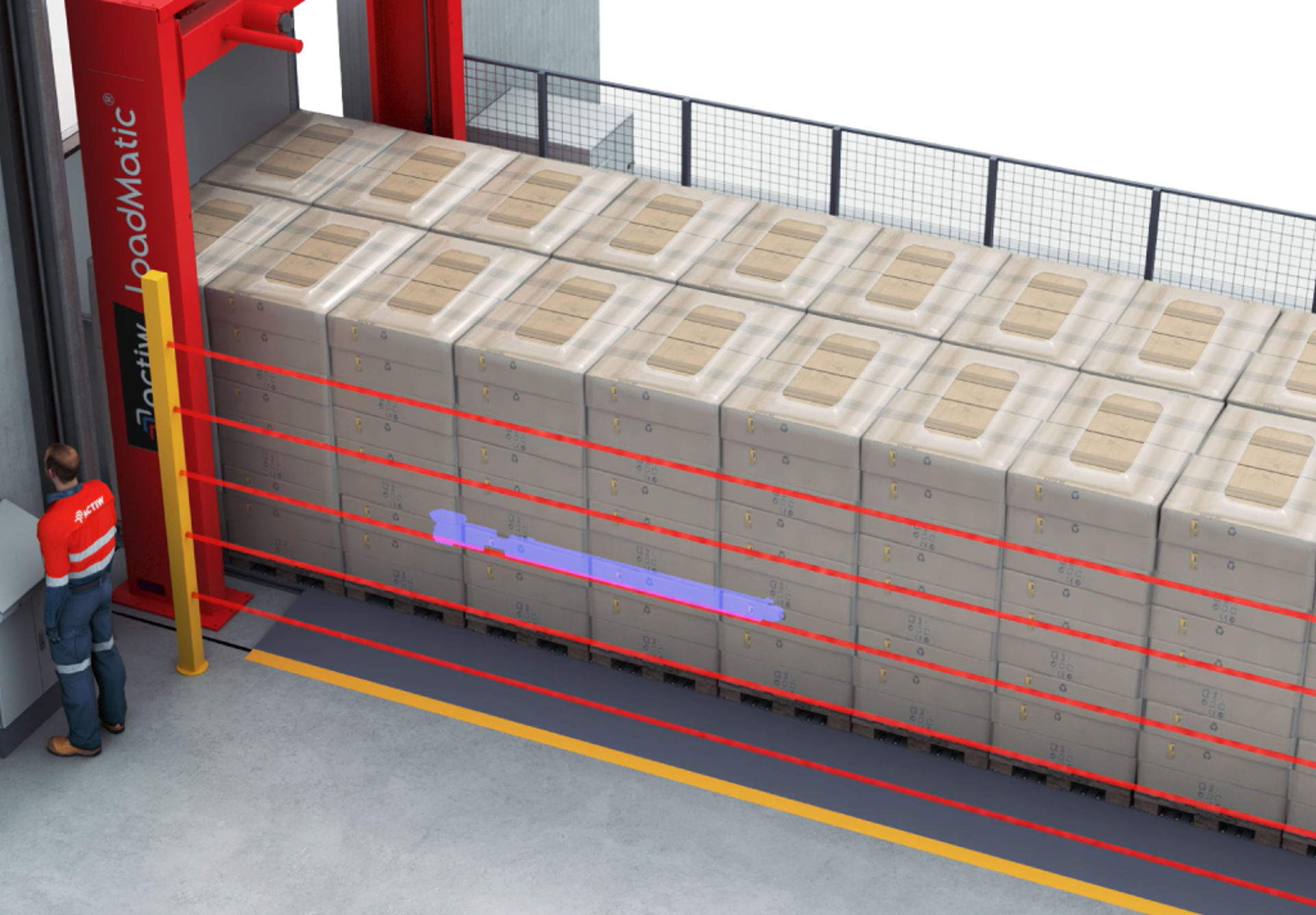

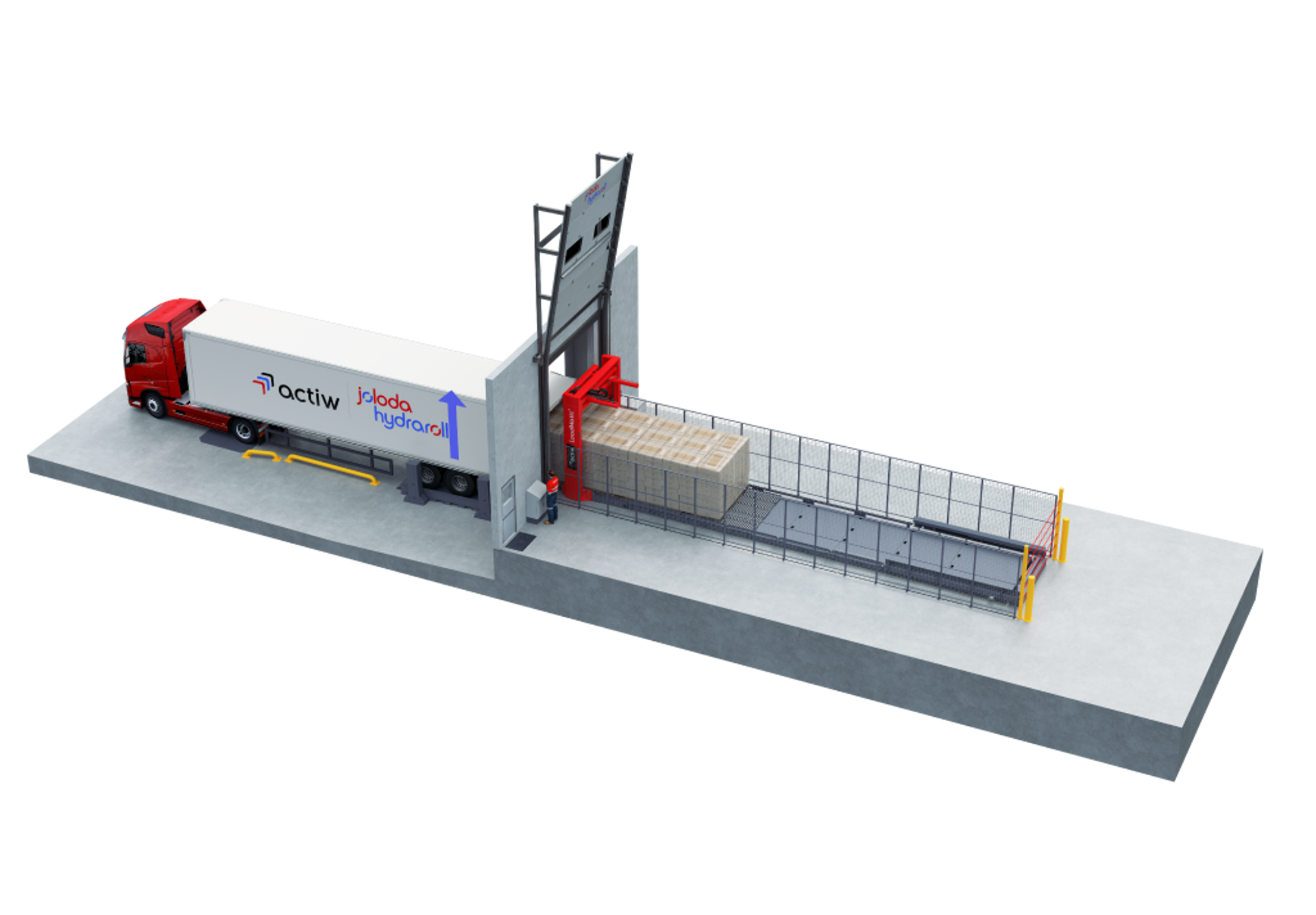

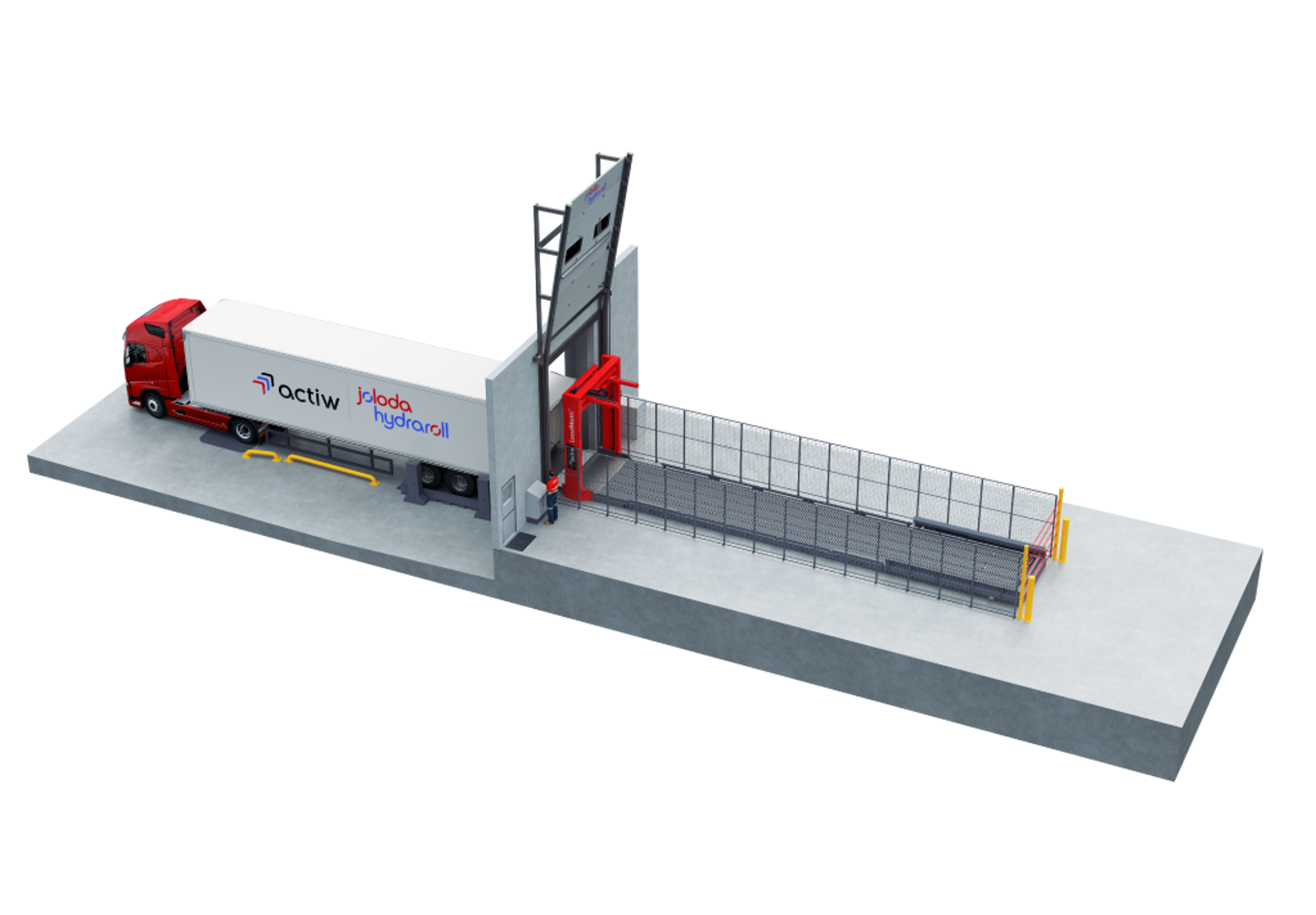

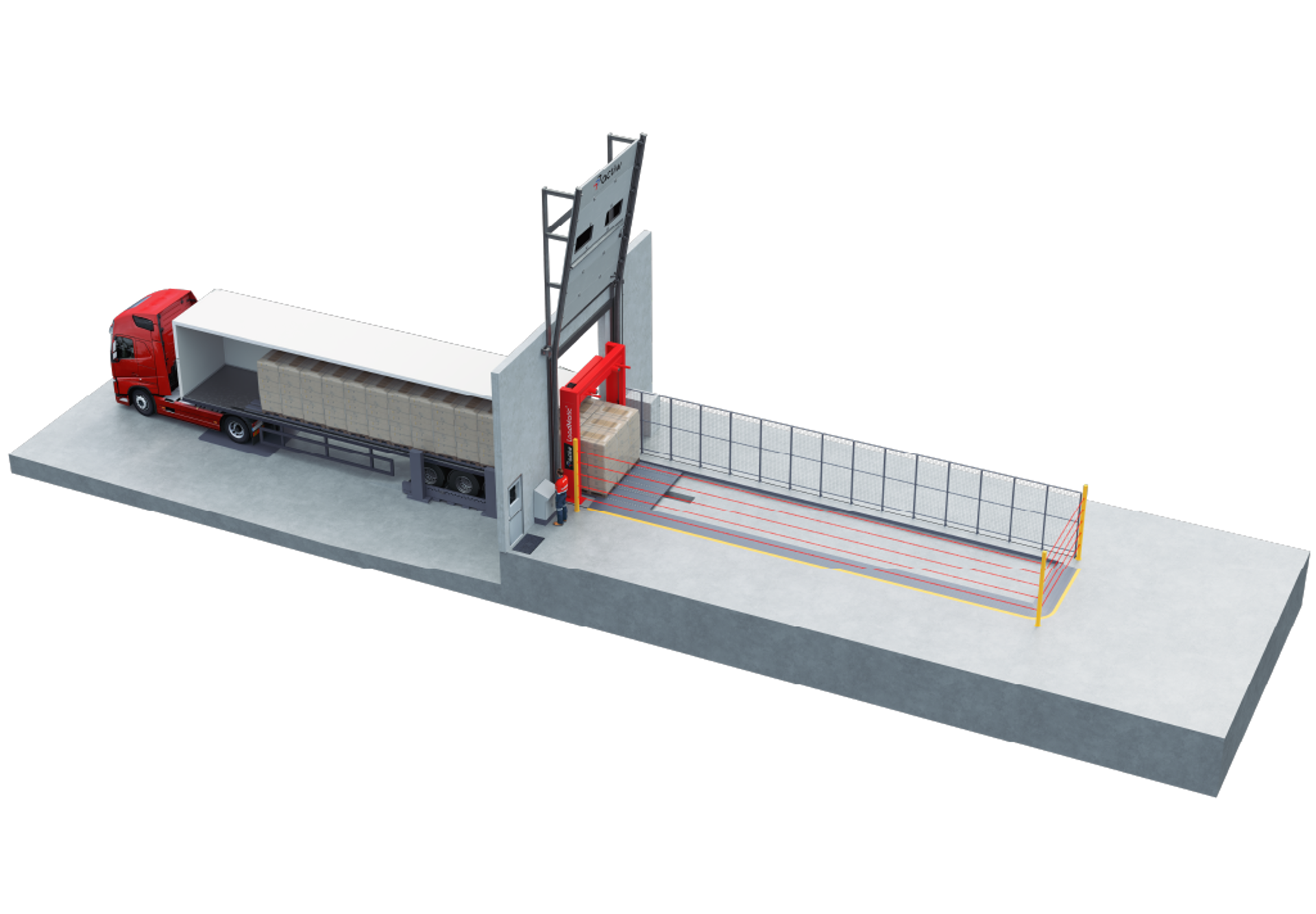

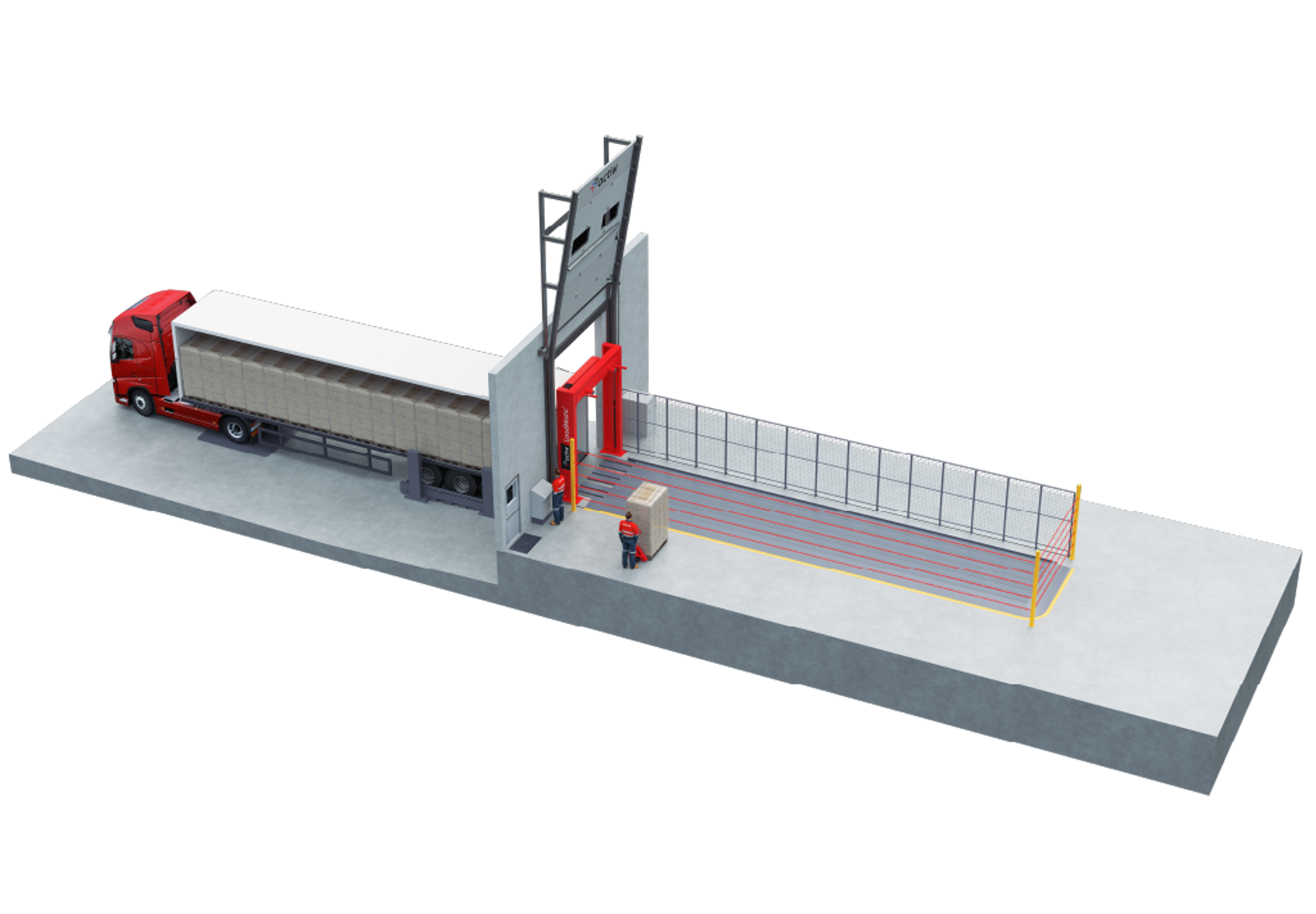

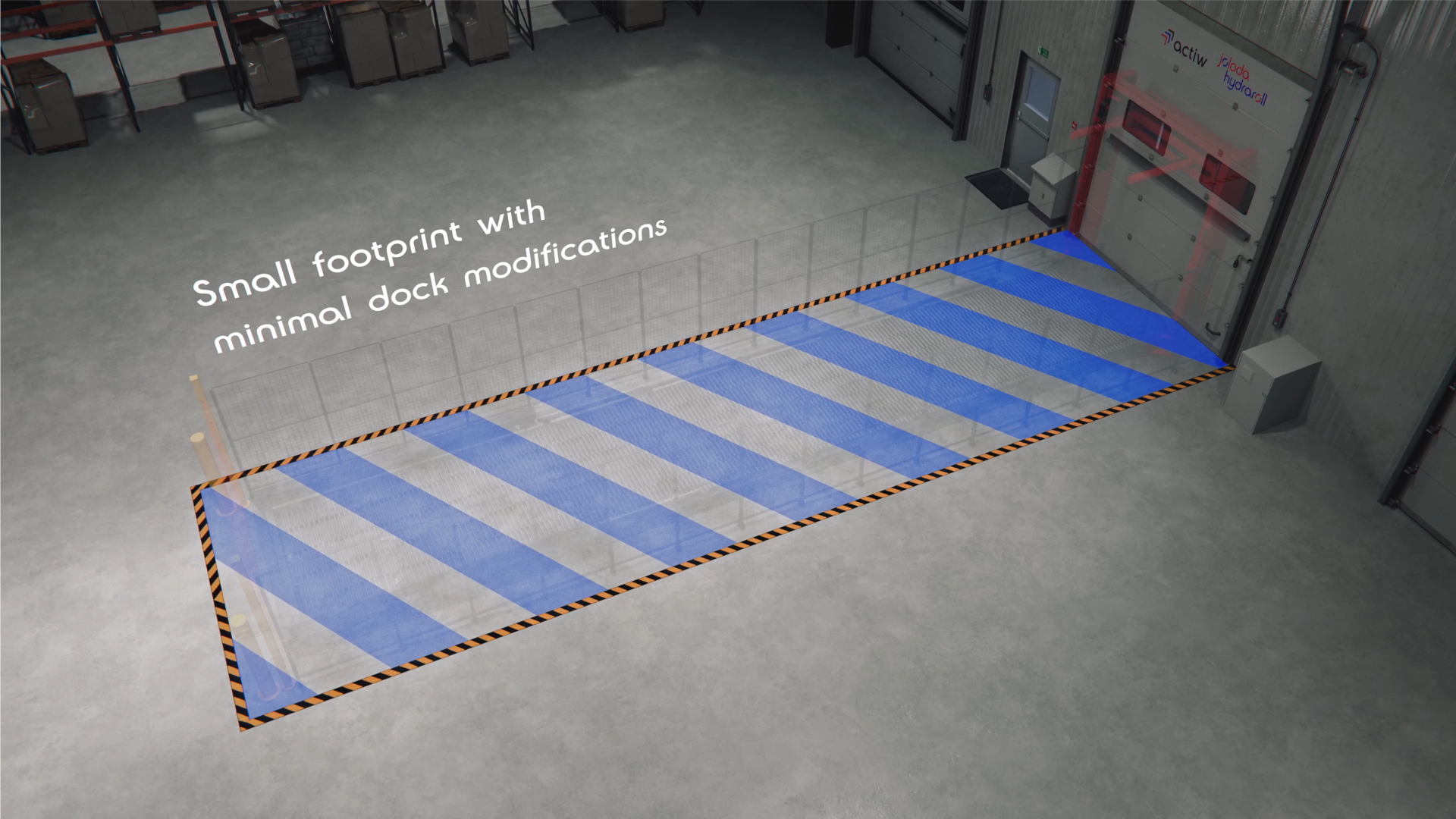

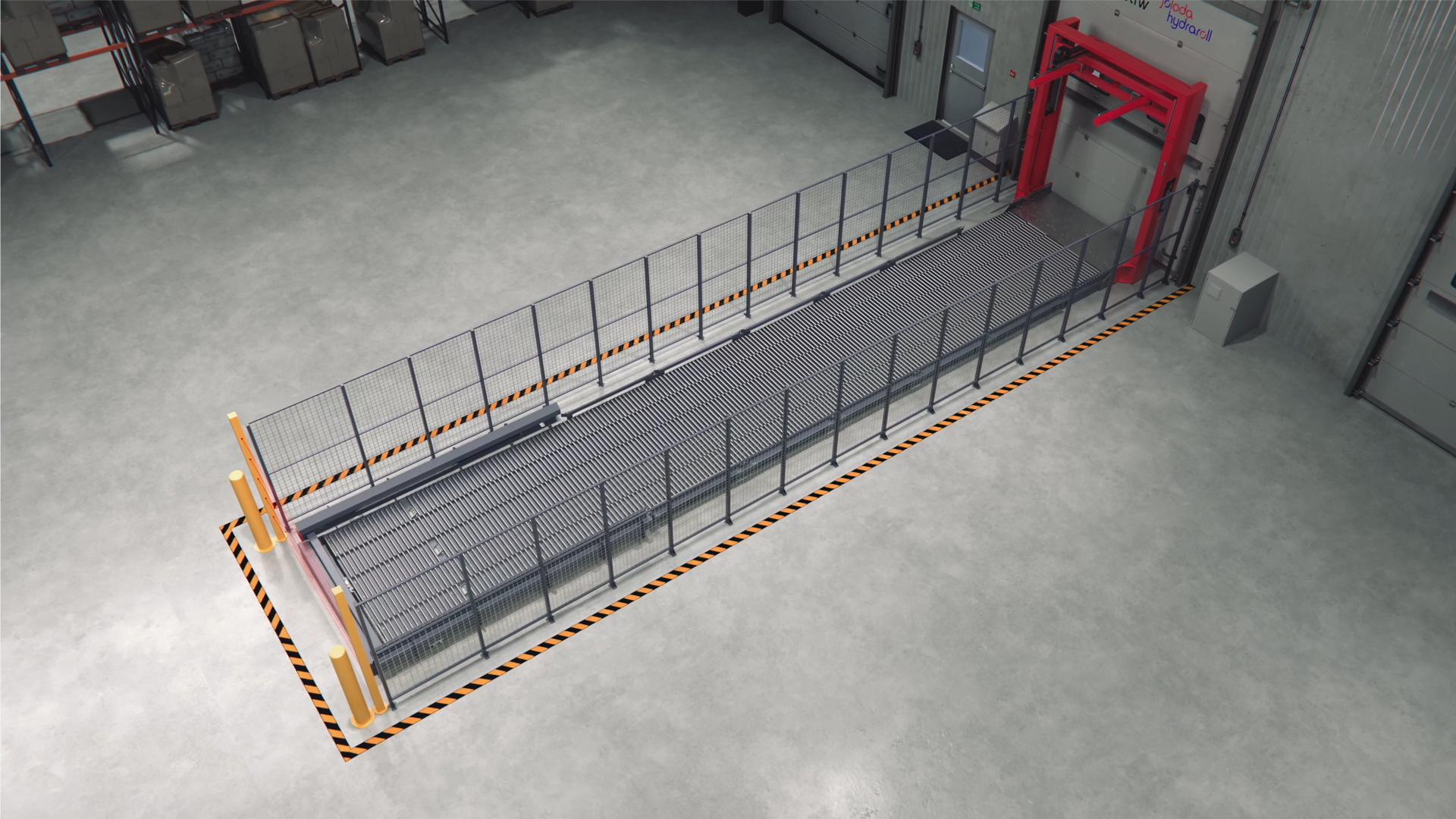

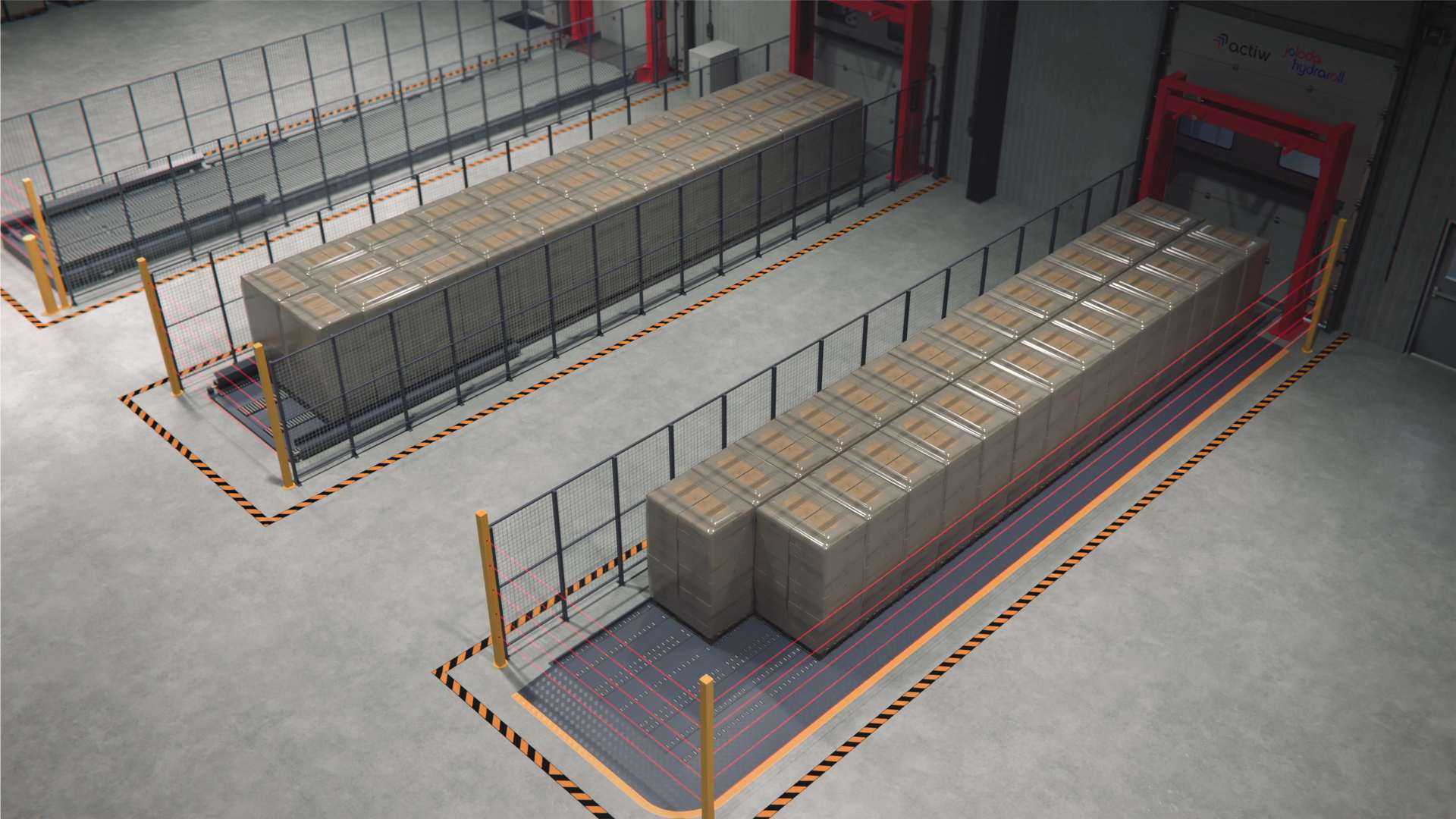

Automated Trailer Loading Systems (ATLS) are often considered the domain of large-scale manufacturing facilities and distribution centres operating shuttle runs between a factory and warehouse. However, new solutions offering more cost and capability options and zero trailer modifications mean a much wider range of businesses stand to benefit - such as those operating in Direct-to-Consumer (D2C) applications where 3PLs will often send any available trailer to transport goods. Tomi Korhonen, Managing Director, Actiw Oy - part of the Joloda Hydraroll Group, explains.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW