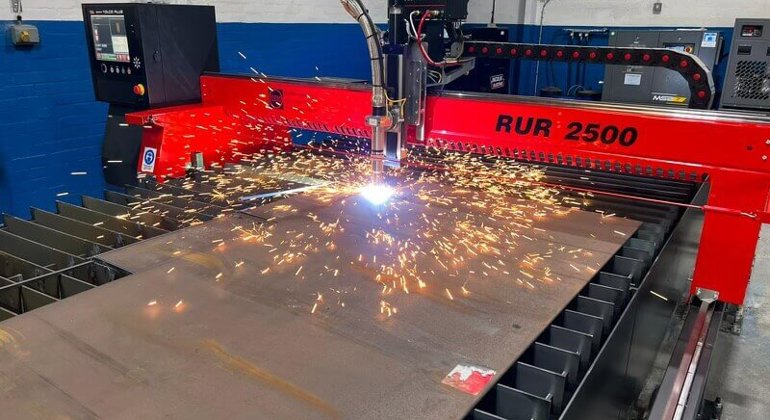

We have recently invested in a new, state-of-the-art Plasma Cutter for our manufacturing facility in Anglesey, Wales. The investment in the new equipment will boose the manufacturing capacity and capabilities in the facility and enable us to bring more of the component manufacturing processes in-house.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW