Teams work with a high volume of lots of different loose materials in logistics. This can make transferring them in and out of factories and warehouses, and in and out of trailers and containers, a real challenge.

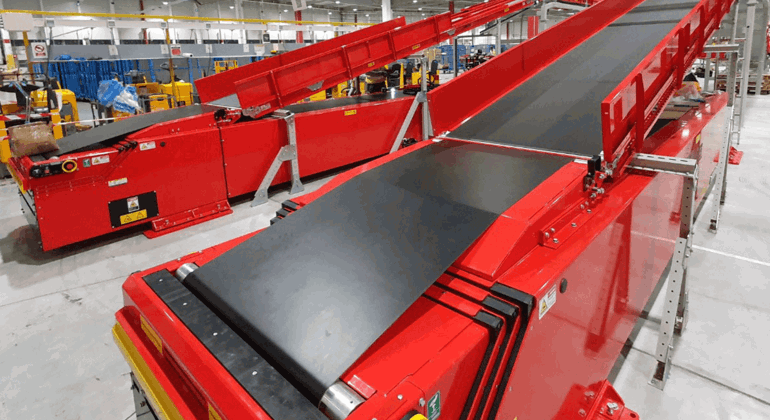

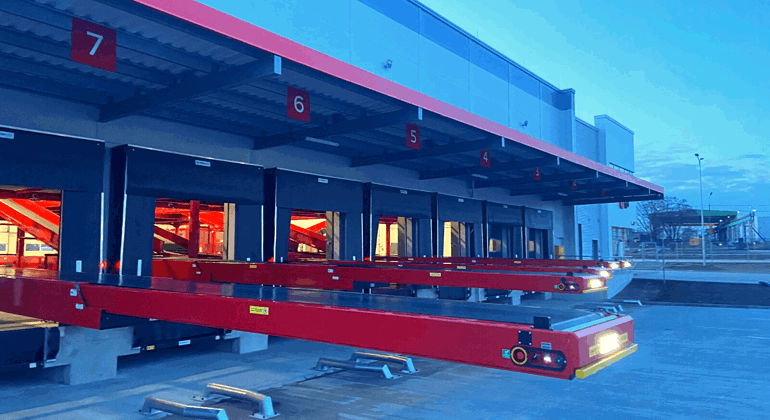

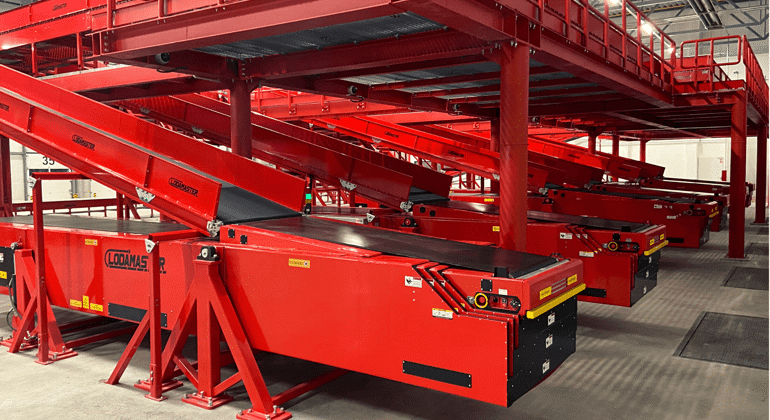

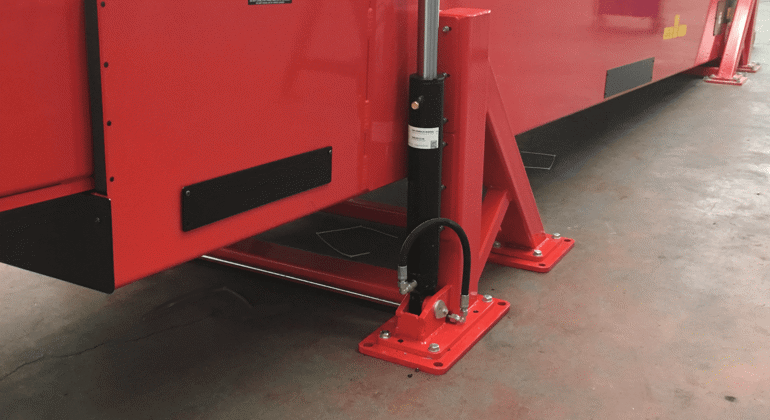

Telescopic Conveyors are one piece of equipment businesses might use for handling bulk loads of loose items. These extendable loading conveyors are highly efficient at handling loose materials in high volumes.

Below is a look at telescopic conveyors for this purpose, other optimum applications for them, how to choose a suitable telescopic conveyor and the benefits of using one. We’ll also discuss the customised telescopic conveyor solutions and related services we offer.

But first, we begin by answering a simple question: what is a telescopic conveyor?

book a free conveyor assessment

We'll visit you to perform a thorough conveyor assessment and identify opportunities to improve your logistics processes.

BOOK NOW