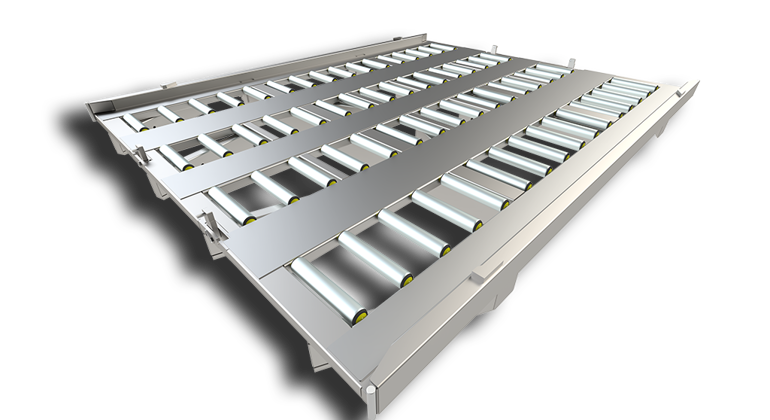

The term ‘Ground Handling Equipment’, also known as ‘Ground Support Equipment’ (GSE), describes the range of tools and devices used to service aircraft while it’s on the ground. These can be simple devices, such as aircraft jacks, or more complex ones, including ground power units, loading equipment and other equipment.

Below is an in-depth look at ground handling, ground handling equipment and health and safety issues when working with air cargo and GSE. We’ll also look at the role of GSE in air cargo operations and discuss how our own systems and other equipment can support ground handling teams, air freight carriers and other logistics personnel who work with air cargo at airports.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW