The Government offers an extremely useful guide on securing loads. We’ve picked out some important points for securing loads, and you can find more in this helpful video and on the Government website:

- The load should go as close to the bulkhead of the trailer as possible. If there are any gaps between the load and the bulkhead, you can place blocking elements in the trailer to help secure the load.

- Direct lashings are used for machinery and, to prevent the load from moving, in opposing pairs, whereas frictional lashings secure many different types of loads, are placed over the load itself and should be as vertical as possible. The type of lashing you choose will depend on the weight of the load, the friction between the load and the load bed, the number of tensioners you’re using, the lashing rating and the angle of the lashing to the load bed.

- Avoid working at height whenever possible.

- It may be more suitable to transport crushable loads in a stillage or box or secure them with rated tarpaulin, rather than secure them with lashes.

- Webbing straps can slacken quickly once the vehicle is in motion, which means that other methods of securing loads that consist of powdered goods may be preferable.

- A stacked load should be stable without lashing.

- You must be able to show that you’ve secured the load properly. A load plan (or load docket) provides everyone information about the load and how you’ve secured it.

Ensuring the vehicle is fit for its purpose

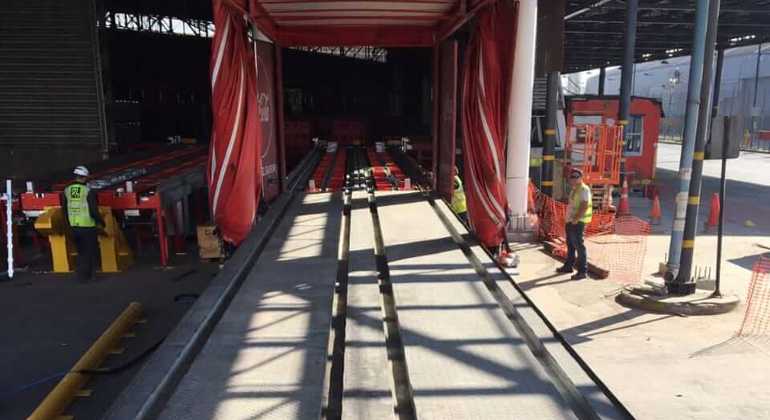

When buying a vehicle, consider the type(s) of load you’re transporting. Specialist companies can advise you correctly on the right load securing systems you need for your vehicle.

Loading the vehicle properly

You should stack the load as close to the headboard as possible and with the centre of gravity as low as possible. Make sure the load is stable without lashings when stacked. Note that if there’s any damage to the headboard, you should fix this as soon as possible because the headboard is a major part of the load securing system.

If a load isn’t stable by itself, think about how you can support it. This means putting in either a box, a stillage or a transport frame. If the load isn’t against the headboard or if other items could slide over, find a way to stop it from sliding forward. Extra lashings, chocks, blocking or sails are all potential solutions.

choose the right securing system

Not all loads are the same, which means webbing straps or chains aren’t suitable for all loads. Choose a system that allows you to secure the load without creating other unnecessary risks such as manual handling and/or working at height.

Whichever system you choose, the system must secure the load to the vehicle chassis and stop the load from moving around.

Using enough load restraint

Dynamic forces are a lot higher than static forces. When a load is moving (dynamic), it will take more force to secure it than when it’s stationary (static). Drivers and operators can underestimate the level of force it will take to secure a load, and this is when incidents happen.

Communication

Good communication is essential. Often, there are some near misses or minor accidents before a major accident finally happens. It’s important to report these incidents so that operators can act appropriately to avoid more serious ones in the future.

Drivers should have information about the loads they’re carrying, how to unload and what to do if their load shifts. If the driver hasn’t loaded or unloaded their trailer, this information is especially important. Ideally, a loading plan should be created and provided so that everyone involved in the operation is aware of all the details around the load.

About your loading restraint system

Even when a vehicle is moving at low speeds, the forces acting on the load can be powerful enough to move it. As for heavy loads, these can move and do, so never rely on the weight of the load alone to hold it in place. Once the vehicle is moving, the forces that prevent the load from moving will be higher than if the load was stationary.

The combined strength of a load restraint system must be enough to withstand a forwards force not less than the total weight of the load to stop it from moving under severe braking, and half the weight of the load moving sideways and backwards.

The consequences of securing a load incorrectly

Not securing a load properly can have grave consequences, the most obvious of these being death or serious injury. These consequences could happen to the driver, other road users or anyone involved in unloading the vehicle.

Common incidents as a result of unsecured loads include:

- items falling out of the vehicle during unloading, forcing someone to jump out of the way and fall;

- items falling out and hitting someone stood next to the vehicle when the curtain lifts;

- people slipping on the load bed because items have fallen over during the journey and the recipients have had to then unload them by hand;

- damage to goods, property or the infrastructure (the consumer then picks these up);

- damage to roads, leading to greater wear and tear on vehicles and increasing overheads for the operator.

A damaged reputation

An unsecured load can harm a company’s corporate reputation. This can arise through bad press around the incident and also via loss of contracts because of damaged goods etc.

Prosecution

The death of an employee or member of the public, or an injury to them, due to negligence on their part could lead to you facing a prosecution. The possible view of negligence is that of ignorance or lack of efficient processes. A company, individual or sole trader can receive major fines for this.

It’s possible to see one example of this on the HSE website. According to a press release from December 2021 on the site, a cardboard manufacturer had to pay £117,585, plus £5,404 in costs, after a forklift truck (FLT) hit a visiting lorry driver and inflicted life-changing injuries. During the loading of the second pallet, the FLT reversed and hit the driver, causing crush injuries to his leg. An investigation by the HSE found the company hadn’t organised the delivery yard in a manner that was safe for vehicles and pedestrians to work safely. There had been a lack of segregation.

Prohibitions and penalties

In some circumstances, a driver may receive a prohibition, which means they won’t be able to move the vehicle until they secured the load. A fixed penalty notice will follow. They’ll have 60 minutes to solve the problem, but if they can’t, implementation of the DVSA immobilisation policy will follow and the driver will have to pay a release fee.

In other circumstances, penalty points may be issued. Often, this happens when the situation is dangerous. For instance, the vehicle is in a dangerous condition because of the weight, suitable purpose, packaging, distribution or adjustment of the load. The driver will receive penalty points, a licence endorsement and possibly an unlimited fine.

Really serious loading breaches can trigger an interview with the DVSA about the roadside incident. Legal proceedings may follow. A report may go out to the Traffic Commissioner, who could take regulatory action against the operator for failure to comply with the undertaking of an operator’s licence. Suspension, curtailment or revocation of the licence are all possible outcomes. The Traffic Commission may also take action concerning the driver’s licence, which could affect both the driver and the operator.