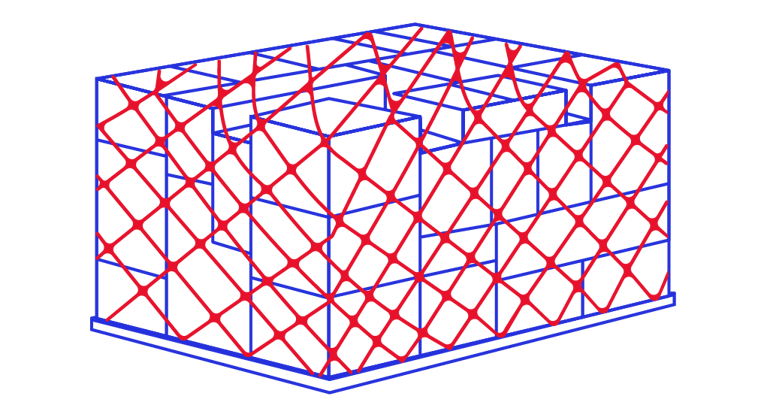

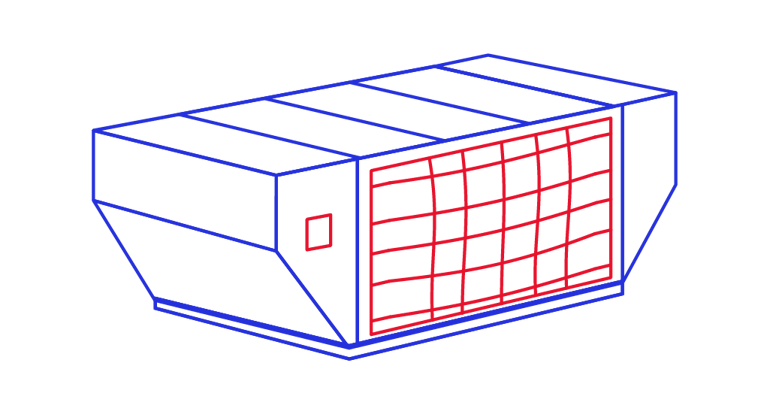

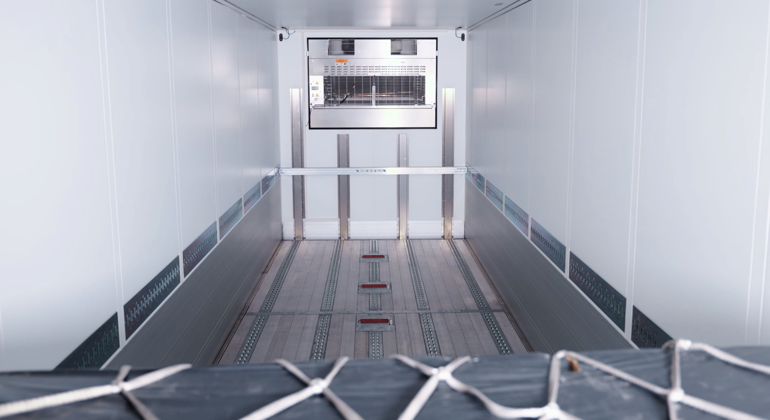

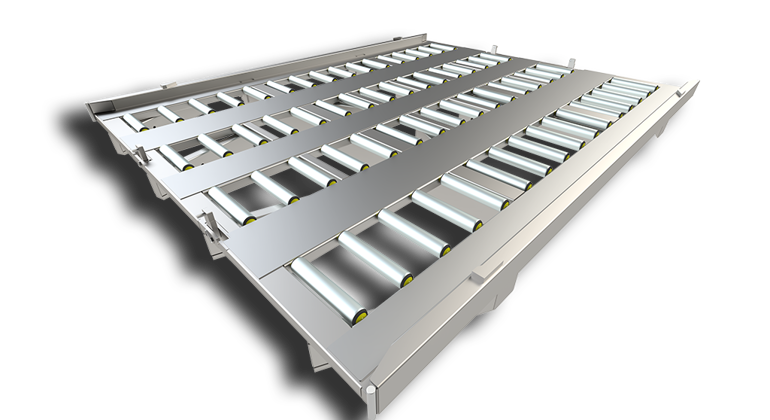

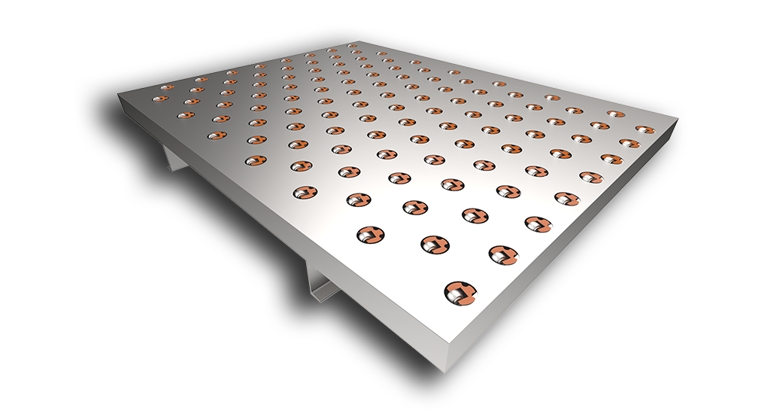

The acronym ‘ULD’ stands for ‘unit load device’, a piece of equipment used in air freight to group and restrain cargo, mail, and small packages on a plane. Often, these devices are either containers or a combination of a pallet and aircraft pallet nets (PMC). ULD pallets play a crucial role in air cargo transportation, enabling transportation units and logistics operators to carry cargo safely and efficiently.

Below we look at ULDs in more depth, discussing ULD types and technical details, aircraft ULDs’ role in aviation and air freight, the safe loading and unloading of ULDs and wider air freight transportation. We also look at how some of our own loading systems can support operators in the air freight industry.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW