Updated 18th December 2025

In-plant logistics (also known as plant logistics or intra-plant logistics) refers to the planning, movement, storage, and control of materials, components, and work-in-progress within a manufacturing or production facility.

Effective in-plant logistics ensures materials arrive at the right place, at the right time, and in the right quantity, directly supporting production efficiency, safety, and on-time delivery.

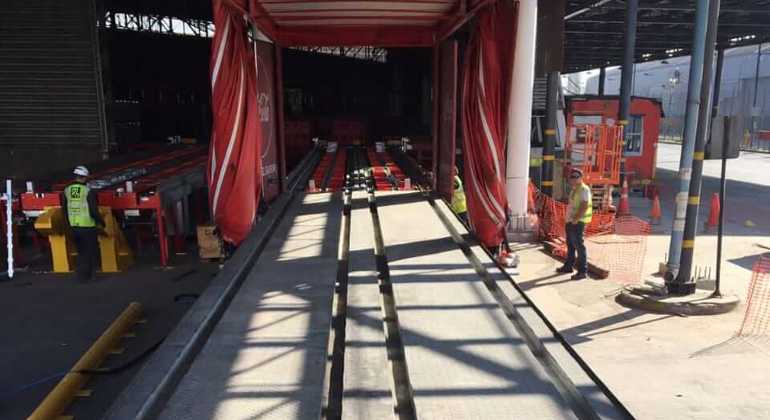

It typically includes: internal transport, line-side supply, material handling equipment, production logistics planning, and the interface between manufacturing lines, warehouses, and outbound dispatch.

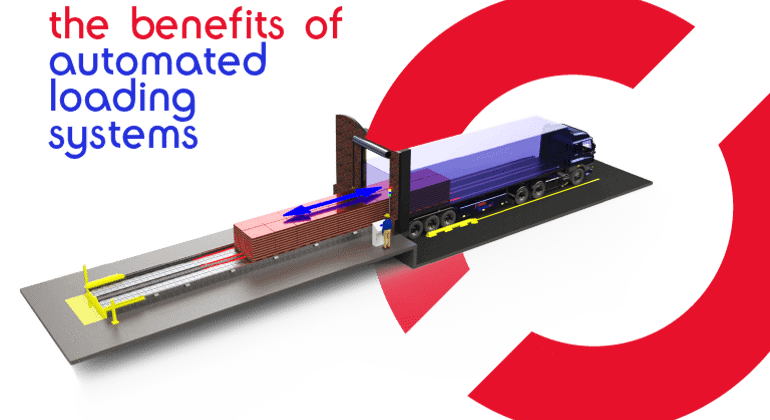

With increasing pressure to reduce costs, improve throughput, and support just-in-time production, manufacturers are turning to automation and smarter material handling systems to optimise in-plant logistics.

In this guide, we explain what in-plant logistics is, why it matters, how it supports production management, and how automated loading and material handling systems can improve efficiency, safety, and flow.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW