Paper reels, or paper rolls, are large rolls of paper wound onto a core, often after making paper. In many cases, they’re used as raw materials for further processing or converting.

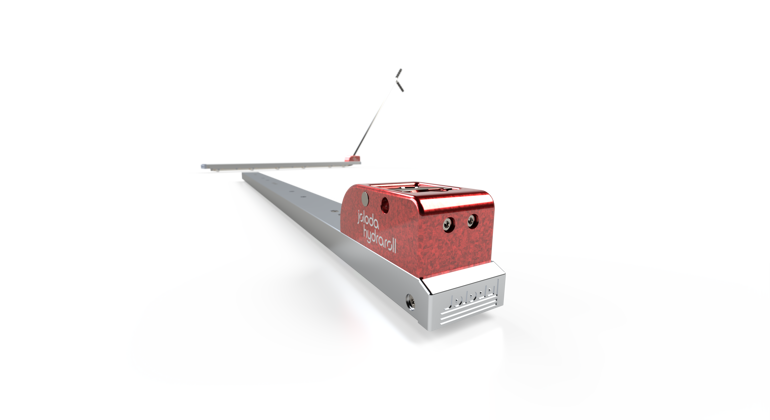

The purpose of the reel, in a paper machine reel, is to wind the continuous sheet produced on a paper or board machine onto a spool and produce jumbo rolls, also called ‘parent rolls’, ready for further processing. Below is a guide to paper reels and the challenges of handling them, plus a look at some of our own paper reel handling equipment and how you can handle paper reels safely with it.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW