‘Distribution centre’ is a term you’ll hear a lot in logistics. You’ll also hear the terms ‘fulfilment centre’ and ‘warehouse’ a lot, and it’s easy to get them all confused.

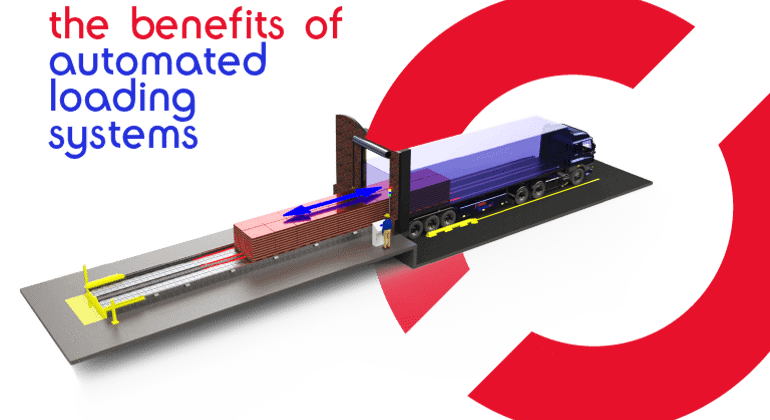

Below we look in depth at what distribution centres are, how they work and the differences between these facilities and warehouses. We discuss key processes in them, the benefits of automated distribution centres and some of the challenges distribution centres face today.

We also look at forklift usage in distribution centres and warehouses, and whether forklifts are still necessary today. Finally, we’ll explain how our own distribution centre solutions support automated distribution centres and reduce forklift usage in them.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW