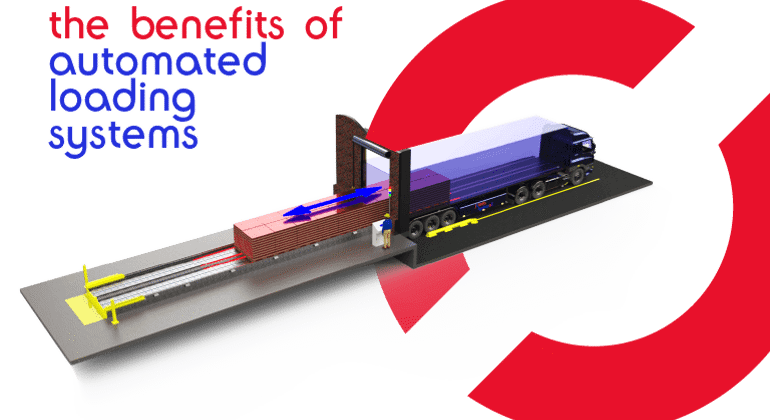

In today's fast-paced and competitive business landscape, optimising supply chain and logistics operations is crucial for companies to maintain a competitive edge.

For this project, we partnered with our Finnish distributor from our Global Distributor Network, NWE Network Engineering Oy Ab, to provide a cutting-edge solution that revolutionised how goods were shuttled between a factory and a warehouse.

This case study delves into how our Automated Loading Systems, combined with Automated Load Securing Systems from NWE, significantly improved Bjelin's logistics operations, helping to maintain their clean-track record of no accidents in their factory and new warehouse; whilst improving operational efficiency and reducing their carbon footprint.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW